air rock drill

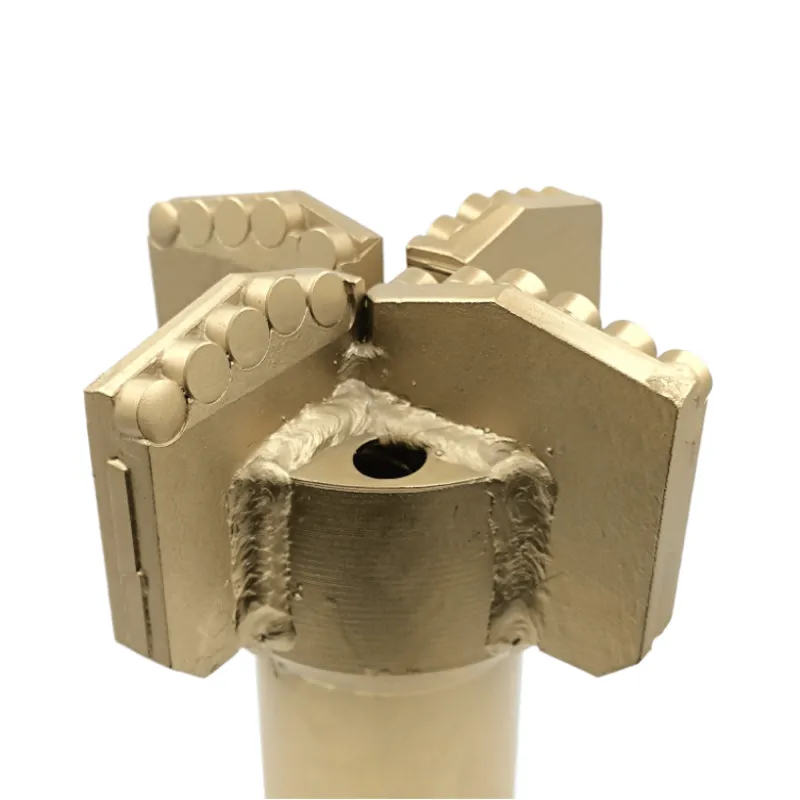

The air rock drill represents a pinnacle of engineering innovation in mining and construction equipment. This powerful tool utilizes compressed air to deliver high-impact force for breaking and drilling through hard rock surfaces. Operating through a pneumatic mechanism, the air rock drill converts compressed air power into mechanical energy, creating rapid percussion movements that efficiently penetrate rock formations. The drill consists of essential components including the air motor, rotation mechanism, percussion system, and drill steel, working in harmony to achieve optimal drilling performance. Modern air rock drills incorporate advanced features such as adjustable impact frequency, ergonomic designs for operator comfort, and dust suppression systems for safer operation. These drills find extensive applications in mining operations, quarrying, construction projects, and tunnel excavation. They excel in both vertical and horizontal drilling scenarios, offering versatility across different working conditions. The tool's robust construction ensures reliability in demanding environments, while its relatively simple mechanical design facilitates maintenance and repairs. Users can select from various bit sizes and styles to match specific drilling requirements, making it adaptable to different rock compositions and project specifications. The integration of noise reduction technology and vibration dampening systems has significantly improved operator safety and comfort, addressing traditional concerns in pneumatic drilling operations.