The air leg rock drill represents one of the most critical pieces of equipment in modern mining and construction operations. These pneumatic drilling machines have revolutionized the way professionals approach rock excavation, tunneling, and quarrying projects. Understanding the intricacies of selecting the right air leg rock drill can significantly impact operational efficiency, project timelines, and overall cost-effectiveness. This comprehensive guide explores the essential factors that industry professionals must consider when investing in this vital equipment.

Understanding Air Leg Rock Drill Technology

Core Mechanisms and Operating Principles

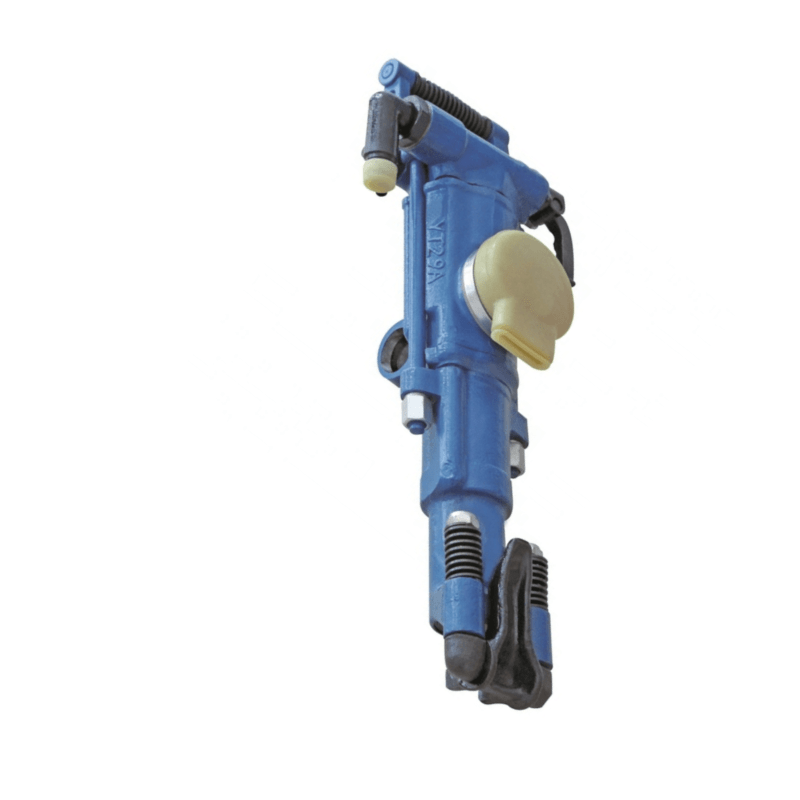

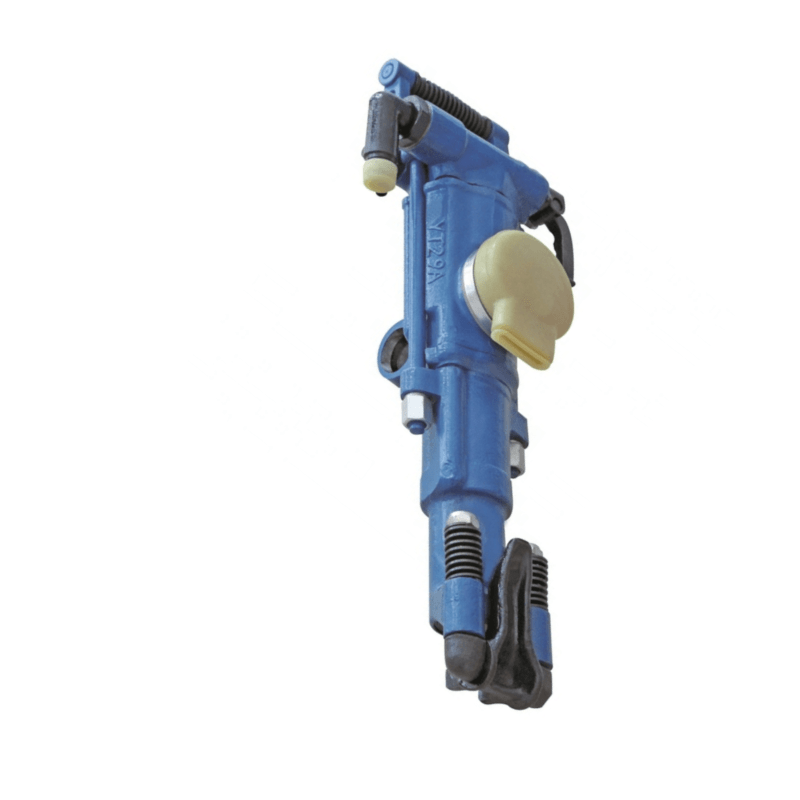

The fundamental operation of an air leg rock drill relies on compressed air to generate powerful percussive forces that fracture rock formations. The pneumatic system creates rapid hammer-like impacts while simultaneously rotating the drill bit, ensuring efficient material removal. The air leg component provides essential support and positioning control, allowing operators to maintain precise drilling angles and depths across various rock types.

Modern air leg rock drill systems incorporate advanced dampening mechanisms that reduce operator fatigue while maximizing drilling precision. The compressed air not only powers the percussive action but also serves as a flushing medium, clearing debris from the drill hole and maintaining optimal cutting conditions. This dual-purpose air system distinguishes these machines from conventional rotary drilling equipment.

Pneumatic System Components

The pneumatic architecture of an air leg rock drill consists of several critical components that work in harmony to deliver consistent performance. The air distribution valve regulates pressure flow to both the percussion mechanism and the rotation motor, ensuring balanced operation across different drilling conditions. High-quality sealing systems prevent air leakage, maintaining efficiency and reducing operational costs.

Advanced air leg rock drill models feature sophisticated pressure regulation systems that automatically adjust to varying rock hardness levels. These adaptive systems optimize drilling parameters in real-time, maximizing penetration rates while minimizing wear on cutting tools. The integration of precision-engineered components ensures reliable operation even in demanding underground environments.

Performance Characteristics and Specifications

Power Output and Drilling Capacity

Evaluating the power specifications of an air leg rock drill requires understanding the relationship between air consumption, impact energy, and drilling diameter capabilities. Professional-grade units typically operate within 4-7 bar pressure ranges, delivering impact energies between 80-150 joules per blow. The drilling diameter capacity generally spans from 32mm to 45mm, accommodating various blasting patterns and excavation requirements.

The correlation between air consumption and drilling efficiency directly impacts operational costs and compressor requirements. High-performance air leg rock drill systems optimize this relationship through advanced valve timing and chamber design, achieving superior penetration rates with reduced air consumption. Understanding these specifications enables informed decision-making regarding equipment selection and operational planning.

Weight Distribution and Ergonomics

The ergonomic design of an air leg rock drill significantly influences operator productivity and safety in underground environments. Optimal weight distribution between the drilling unit and support leg reduces physical strain while maintaining precise control over drilling operations. Modern designs incorporate advanced materials that reduce overall weight without compromising structural integrity or performance capabilities.

Vibration reduction technology plays a crucial role in operator comfort and long-term health considerations. Leading air leg rock drill manufacturers implement sophisticated dampening systems that minimize transmitted vibrations while preserving drilling efficiency. These ergonomic improvements directly translate to increased productivity and reduced operator fatigue during extended drilling operations.

Application-Specific Requirements

Mining and Quarrying Applications

Mining operations demand air leg rock drill systems capable of consistent performance across diverse geological conditions. Underground mining environments require equipment that can handle varying rock hardness levels while maintaining precise blast hole patterns. The reliability of the drilling equipment directly impacts production schedules and extraction efficiency in commercial mining operations.

Quarrying applications present unique challenges that require specialized air leg rock drill configurations. Open-pit operations often involve extensive drilling programs where equipment durability and maintenance requirements become critical factors. The ability to maintain consistent drilling parameters across large-scale operations determines the overall success of quarrying projects.

Construction and Tunneling Projects

Construction projects utilizing an air leg rock drill for foundation work and excavation require equipment that can adapt to confined spaces and precise positioning requirements. Urban construction environments demand low-noise operation and efficient debris removal systems to minimize environmental impact. The versatility of these drilling systems makes them essential tools for modern construction methodologies.

Tunneling applications require air leg rock drill systems with exceptional reliability and consistent performance characteristics. The confined nature of tunnel construction limits equipment access and maintenance opportunities, making reliability a paramount concern. Advanced monitoring systems integrated into modern drilling equipment provide real-time performance feedback, enabling proactive maintenance scheduling.

Selection Criteria and Evaluation Process

Technical Specifications Assessment

Selecting the optimal air leg rock drill requires systematic evaluation of technical specifications against specific operational requirements. Key performance indicators include impact frequency, rotation speed, air consumption rates, and drilling diameter capabilities. Professional procurement teams must balance these technical parameters with budget constraints and long-term operational objectives.

The assessment process should include detailed analysis of manufacturer specifications, independent performance testing data, and user feedback from similar applications. Comparative evaluation of multiple air leg rock drill models enables informed decision-making based on objective performance criteria rather than marketing claims alone.

Maintenance and Service Considerations

Long-term operational costs associated with an air leg rock drill extend far beyond initial purchase price considerations. Maintenance requirements, spare parts availability, and service support infrastructure significantly impact total cost of ownership. Comprehensive evaluation of these factors prevents unexpected operational disruptions and budget overruns.

Service network availability and technical support quality directly influence equipment uptime and productivity levels. Manufacturers with established service networks and comprehensive training programs provide superior value propositions for professional users. The availability of local service technicians and rapid spare parts delivery systems minimizes operational downtime.

Safety Standards and Regulatory Compliance

Industrial Safety Requirements

Operating an air leg rock drill requires adherence to strict safety protocols and regulatory standards established by occupational health organizations. Proper training programs ensure operators understand equipment limitations, safety procedures, and emergency response protocols. Compliance with these standards protects both personnel and organizational liability exposure.

Modern safety features integrated into advanced drilling systems include automatic shut-off mechanisms, pressure monitoring systems, and enhanced visibility components. These safety enhancements reduce accident risk while maintaining operational efficiency. Regular safety audits and equipment inspections ensure continued compliance with evolving regulatory requirements.

Environmental Impact Considerations

Environmental considerations surrounding air leg rock drill operations include noise reduction, dust control, and energy efficiency improvements. Advanced models incorporate noise suppression technology and efficient dust collection systems that minimize environmental impact. These features become increasingly important as environmental regulations continue to evolve.

Sustainable operation practices include proper maintenance scheduling, efficient air compression systems, and responsible disposal of consumable components. Organizations implementing comprehensive environmental management programs demonstrate corporate responsibility while potentially reducing operational costs through improved efficiency.

Cost Analysis and Investment Justification

Total Cost of Ownership Evaluation

Comprehensive cost analysis for air leg rock drill procurement extends beyond initial equipment purchase to include operational expenses, maintenance costs, and productivity improvements. Financial modeling should incorporate equipment lifecycle expectations, utilization rates, and potential productivity gains from upgraded equipment capabilities.

Investment justification requires quantitative analysis of productivity improvements, reduced downtime, and operational cost savings achievable through modern equipment adoption. Advanced air leg rock drill systems often deliver measurable improvements in drilling efficiency, operator productivity, and maintenance requirements that justify premium equipment investments.

Financing Options and Budget Planning

Various financing alternatives enable organizations to acquire advanced air leg rock drill equipment while managing cash flow requirements. Lease options, equipment financing programs, and rental agreements provide flexibility for different operational scenarios and budget constraints. Understanding these options enables optimal financial planning for equipment acquisition.

Budget planning should incorporate potential equipment upgrades, technology improvements, and changing operational requirements over the equipment lifecycle. Forward-thinking procurement strategies account for technological advancement and operational evolution to maximize long-term investment value.

Future Technology Trends

Automation and Digital Integration

The evolution of air leg rock drill technology includes increasing automation capabilities and digital integration features. Advanced models incorporate sensors, data logging capabilities, and remote monitoring systems that enhance operational oversight and maintenance planning. These technological improvements represent the future direction of industrial drilling equipment.

Digital integration enables real-time performance monitoring, predictive maintenance scheduling, and operational optimization through data analysis. Organizations adopting these advanced technologies gain competitive advantages through improved efficiency, reduced downtime, and enhanced operational insights.

Sustainable Design Innovations

Sustainable design principles increasingly influence air leg rock drill development, focusing on energy efficiency, reduced environmental impact, and improved operator safety. Manufacturers investing in research and development continue to introduce innovations that address environmental concerns while maintaining performance standards.

Future innovations may include alternative power sources, advanced materials, and intelligent control systems that optimize performance while minimizing resource consumption. Understanding these trends enables informed decision-making regarding equipment investment timing and technology adoption strategies.

FAQ

What factors determine the appropriate air leg rock drill for specific applications

The selection process should consider rock hardness, drilling diameter requirements, operational environment constraints, and productivity expectations. Technical specifications including impact energy, rotation speed, and air consumption must align with specific application demands and available compressed air capacity.

How do maintenance requirements vary between different air leg rock drill models

Maintenance requirements depend on design complexity, operating environment, and utilization intensity. Premium models often feature enhanced component accessibility, extended service intervals, and comprehensive diagnostic capabilities that reduce maintenance complexity and operational downtime.

What safety considerations are essential when operating air leg rock drill equipment

Essential safety considerations include proper operator training, personal protective equipment requirements, regular equipment inspections, and adherence to established safety protocols. Understanding equipment limitations and emergency procedures prevents accidents and ensures regulatory compliance.

How do operational costs compare between different air leg rock drill systems

Operational costs vary based on air consumption rates, maintenance requirements, consumable replacement frequency, and productivity levels. Higher initial investment in premium equipment often results in lower long-term operational costs through improved efficiency and reduced maintenance requirements.