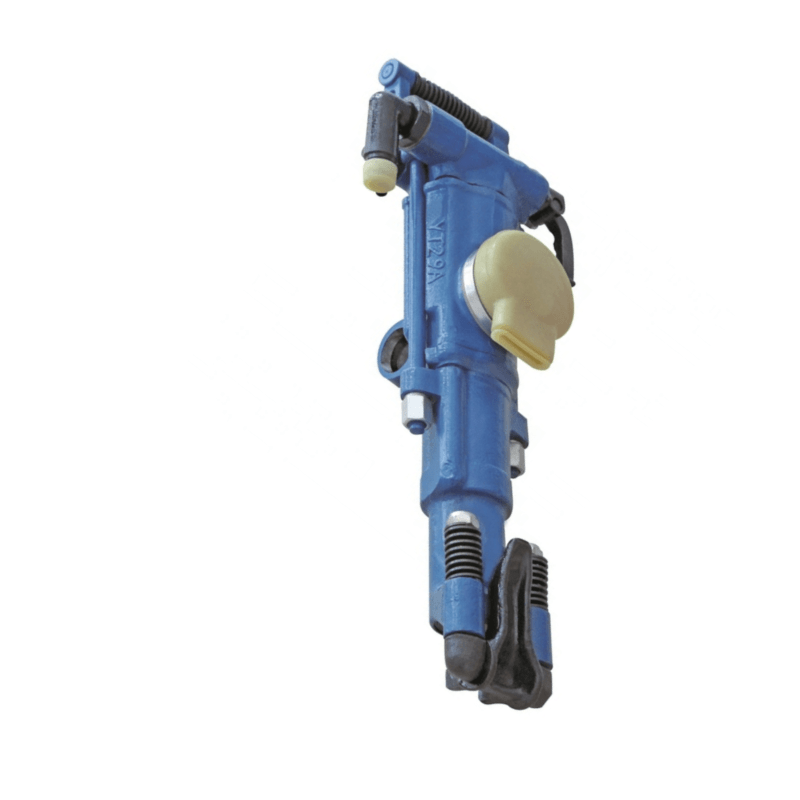

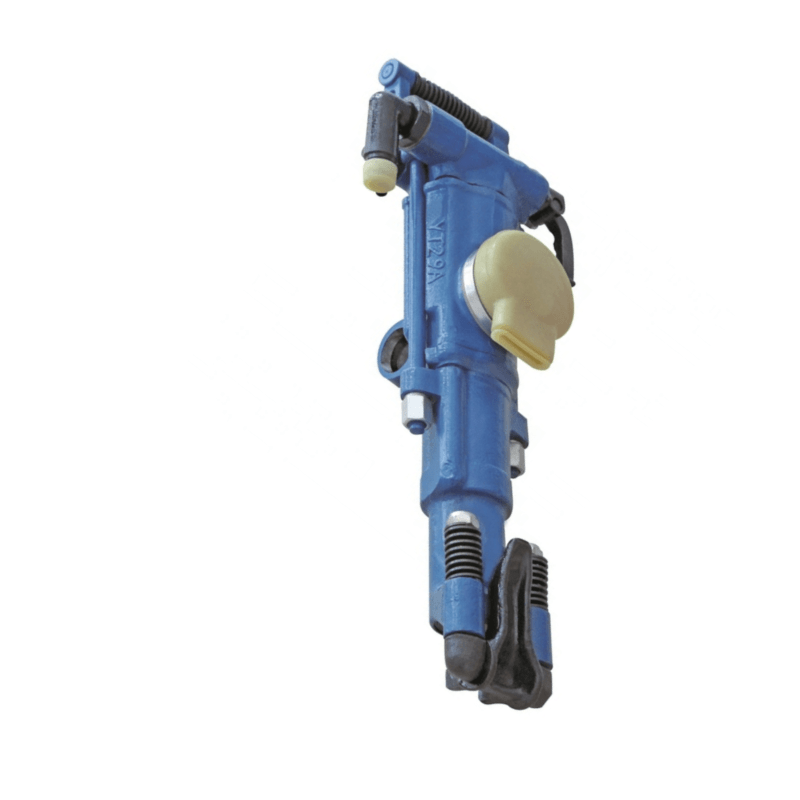

Proper maintenance of your air leg rock drill components ensures optimal performance, extends equipment lifespan, and reduces costly downtime in mining and construction operations. Understanding the critical parts and their maintenance requirements helps operators maintain peak drilling efficiency while preventing unexpected failures that can halt project progress.

Industrial drilling operations demand reliable equipment that can withstand harsh working conditions while delivering consistent results. An air leg rock drill requires systematic maintenance protocols to function at maximum capacity. Regular inspection and replacement of key components prevents operational delays and ensures worker safety during demanding drilling applications.

Essential Components of Air Leg Rock Drill Systems

Primary Drilling Components

The cylinder assembly forms the heart of any air leg rock drill system, housing the piston mechanism that generates the percussive force necessary for effective rock penetration. This component requires regular inspection for wear patterns, scoring, or damage that could compromise drilling performance. Operators should examine cylinder walls for scratches or deep grooves that indicate excessive wear and potential air leakage.

Piston assemblies work in conjunction with cylinder components to create the hammering action essential for rock drilling operations. These parts experience significant stress during operation and require frequent monitoring for cracks, chips, or deformation. Proper lubrication of piston surfaces helps minimize friction and extends component life while maintaining optimal drilling speed.

Steel bits represent the cutting edge of drilling operations, directly contacting rock surfaces and transferring percussive energy for material removal. Regular sharpening and replacement of worn bits maintains drilling efficiency and prevents excessive strain on other drill components. Quality steel bits designed for specific rock types enhance overall system performance.

Air Distribution System Parts

Valve mechanisms control air flow throughout the drilling system, regulating pressure and timing for optimal performance. These precision components require careful maintenance to prevent air leaks that reduce drilling power and increase operating costs. Regular cleaning and lubrication of valve seats ensures proper sealing and extends component service life.

Air hoses and fittings form critical connections throughout the pneumatic system, delivering compressed air to various drill components. Inspection for cuts, abrasions, or loose connections prevents pressure loss and maintains consistent drilling performance. Quality fittings with proper torque specifications ensure reliable air distribution under demanding operating conditions.

Filter assemblies protect internal components from contamination while maintaining air quality throughout the system. Clogged or damaged filters reduce air flow efficiency and allow harmful particles to enter sensitive mechanisms. Regular filter replacement according to manufacturer specifications prevents costly component damage and maintains optimal drilling performance.

Maintenance Scheduling and Inspection Protocols

Daily Maintenance Procedures

Beginning each shift with a comprehensive visual inspection helps identify potential issues before they become costly problems. Operators should examine all external components for obvious damage, loose connections, or signs of excessive wear that could affect performance or safety. This initial assessment takes minimal time but provides valuable insights into equipment condition.

Lubrication checks ensure all moving parts receive adequate protection against friction and wear. Daily application of appropriate lubricants to designated points maintains smooth operation and prevents premature component failure. Using manufacturer-recommended lubricants protects warranty coverage and ensures compatibility with system materials.

Air pressure verification confirms system operating parameters remain within acceptable ranges for safe and efficient operation. Pressure gauges should indicate proper readings according to equipment specifications, with any deviations investigated immediately. Maintaining correct air pressure protects components from damage while ensuring optimal drilling performance.

Weekly Comprehensive Inspections

Detailed examination of wear parts identifies components approaching replacement intervals before failure occurs. Weekly inspections allow operators to plan maintenance activities during scheduled downtime rather than experiencing unexpected equipment failures. This proactive approach minimizes project delays and reduces overall maintenance costs.

System performance testing verifies that the air leg rock drill maintains specified drilling rates and power output under normal operating conditions. Performance degradation often indicates developing problems that require attention before complete component failure occurs. Regular testing provides objective data for maintenance decision-making.

Documentation of inspection findings creates valuable maintenance records that help identify patterns and optimize replacement schedules. Detailed records enable predictive maintenance strategies that reduce costs while improving equipment reliability. Historical data guides inventory management and helps justify equipment upgrade decisions.

Critical Replacement Parts and Inventory Management

High-Wear Components

Drill steel and bits experience the most severe operating conditions and require frequent replacement to maintain productivity. Establishing appropriate inventory levels based on drilling conditions and usage patterns prevents costly delays when replacements become necessary. Quality replacement parts ensure consistent performance and protect other system components from excessive stress.

Seals and gaskets throughout the air leg rock drill system prevent air leaks that reduce efficiency and increase operating costs. These rubber components deteriorate over time due to temperature cycles, chemical exposure, and mechanical stress. Maintaining adequate seal inventory enables prompt replacement during scheduled maintenance intervals.

Valve components including springs, seats, and actuators require periodic replacement to maintain proper air flow control. These precision parts affect overall system timing and performance, making quality replacements essential for optimal operation. Proper storage conditions preserve replacement part quality until installation becomes necessary.

Predictive Replacement Strategies

Component life tracking enables maintenance teams to predict replacement needs based on actual usage data rather than arbitrary schedules. This approach optimizes inventory investment while ensuring critical parts remain available when needed. Advanced tracking systems provide alerts when components approach recommended replacement intervals.

Condition monitoring techniques help extend component life by identifying optimal replacement timing based on actual wear rather than estimated service hours. Vibration analysis, pressure monitoring, and performance testing provide objective data for maintenance decisions. These technologies maximize component utilization while preventing unexpected failures.

Supplier partnerships ensure reliable access to quality replacement parts when standard inventory becomes depleted. Establishing relationships with multiple suppliers provides backup options and competitive pricing for ongoing maintenance needs. Quality suppliers offer technical support and application guidance for optimal part selection.

Troubleshooting Common Air Leg Rock Drill Issues

Performance Degradation Problems

Reduced drilling speed often indicates worn drill bits, insufficient air pressure, or internal component damage requiring immediate attention. Systematic diagnosis helps identify root causes and appropriate corrective actions. Performance monitoring provides early warning of developing problems before complete equipment failure occurs.

Excessive vibration typically results from worn bearings, damaged drill steel, or improper component alignment within the air leg rock drill assembly. These conditions create operator fatigue and accelerate wear throughout the system. Prompt correction prevents secondary damage and maintains safe operating conditions.

Air consumption increases usually indicate internal leakage, worn seals, or valve problems that reduce system efficiency. Higher air consumption directly impacts operating costs and may indicate developing component failures. Regular consumption monitoring helps identify problems before they become severe.

Component Failure Analysis

Premature part failure often results from operating conditions exceeding design parameters, inadequate maintenance, or installation errors. Failure analysis provides insights for improving maintenance procedures and preventing recurrence. Understanding failure modes helps optimize replacement part selection and inventory planning.

Environmental factors including dust, moisture, and temperature extremes affect component life and require protective measures. Proper storage, handling, and installation procedures minimize environmental damage to sensitive parts. Protective equipment and operating procedures help extend component service life in challenging conditions.

Operator training ensures proper equipment handling and maintenance procedure compliance that prevents avoidable component damage. Well-trained operators recognize early warning signs of developing problems and take appropriate corrective actions. Ongoing training programs keep operators current with best practices and new technologies.

Safety Considerations During Maintenance Operations

Personal Protective Equipment Requirements

Comprehensive personal protective equipment protects maintenance personnel from compressed air hazards, flying debris, and chemical exposures during air leg rock drill servicing. Safety glasses, hearing protection, and appropriate clothing prevent injuries during routine maintenance activities. Proper PPE selection based on specific hazards ensures adequate protection without hindering work efficiency.

Respiratory protection becomes essential when working in dusty environments or handling lubricants and cleaning solvents. Proper respirator selection and fit testing ensures adequate protection against airborne contaminants. Regular filter replacement maintains protection effectiveness throughout maintenance operations.

Hand protection prevents cuts and chemical exposure while allowing sufficient dexterity for precision maintenance tasks. Cut-resistant gloves with chemical compatibility protect against multiple hazards encountered during air leg rock drill maintenance. Proper glove selection balances protection with operational requirements.

Lockout and Tagout Procedures

Energy isolation prevents accidental equipment startup during maintenance activities that could cause serious injury or death. Comprehensive lockout procedures address compressed air, electrical, and mechanical energy sources. Proper isolation verification ensures complete energy control before beginning maintenance work.

Clear communication protocols inform all personnel about ongoing maintenance activities and equipment status. Standardized tags and locks provide visual confirmation of energy isolation and maintenance authorization. Multiple person lockout procedures ensure coordination when several technicians work on the same equipment.

Pressure release procedures safely dissipate stored energy before beginning internal component work on air leg rock drill systems. Gradual pressure reduction prevents sudden component movement that could cause injury. Proper venting techniques protect both personnel and equipment during maintenance operations.

FAQ

How often should air leg rock drill components be inspected for wear

Daily visual inspections should check for obvious damage or loose connections, while comprehensive wear assessments require weekly examination of critical components. High-stress parts like drill bits and seals need more frequent monitoring based on operating conditions and usage intensity. Severe operating environments may require daily detailed inspections to prevent unexpected failures.

What are the most common replacement parts needed for air leg rock drill maintenance

Drill bits, seals, gaskets, and valve components represent the most frequently replaced parts in air leg rock drill systems. These components experience the highest stress and wear rates during normal operation. Maintaining adequate inventory of these critical parts prevents extended downtime when replacements become necessary.

How can operators extend the service life of air leg rock drill components

Proper lubrication, regular cleaning, and adherence to manufacturer operating specifications significantly extend component life. Avoiding operation beyond design limits and prompt attention to developing problems prevents accelerated wear. Quality replacement parts and proper installation procedures also contribute to extended service intervals.

What safety precautions are essential during air leg rock drill maintenance

Complete energy isolation through lockout/tagout procedures prevents accidental startup during maintenance work. Appropriate personal protective equipment protects against compressed air hazards, chemical exposure, and mechanical injuries. Proper ventilation and respiratory protection become essential when working with cleaning solvents or in dusty environments.