Deepen the market segment and drive global growth with product strength and customer value

In the first quarter of 2025, Tianjin Realon Mining Co., Ltd., as the world's leading supplier of pneumatic mining tool solutions, focused on four core products: pneumatic rock drills, drill bits, drill rods, and pneumatic picks. With "technological innovation, customer first, and global layout" as the strategic core, it achieved a steady start in the complex international market. As of March 31, the company's core product exports increased by 28% year-on-year, the number of new customers increased by 35%, and its products covered 82 countries and regions around the world, continuing to consolidate its benchmark position in the segment.

Ⅰ. Quarterly performance: core data demonstrates growth resilience

1. Sales performance rose against the trend

Overall growth: The export value of mining tools increased by 28% year-on-year, among which the order volume of the four major categories of pneumatic rock drills, drill bits, drill rods, and pneumatic picks increased by 30%, 35%, 25%, and 40% respectively, and the proportion of hard mining tools (such as tungsten carbide drill bits) increased to 45%.

Regional breakthrough: The order volume in the Southeast Asian market increased by 40%, relying on the laterite nickel mining boom to reach an annual framework agreement; the Middle East market increased by 50% month-on-month, entering the high-end engineering supply chain through the Dubai BIG5 exhibition, and serving the Saudi Arabia NEOM Future City Tunnel Project; the Latin American market (Brazil, Chile) increased by 30%, focusing on the demand for copper and gold mining, and the order volume of customized drill rod sets accounted for 60%.

2. Cooperation with major customers and projects

Provide low-vibration and noise-reducing rock drills for Chinese overseas projects and tunnel projects, and the equipment procurement volume for a single project exceeded 500 units, helping customers meet the EU's stringent environmental protection standards (noise ≤85dB, vibration value ≤6m/s²).

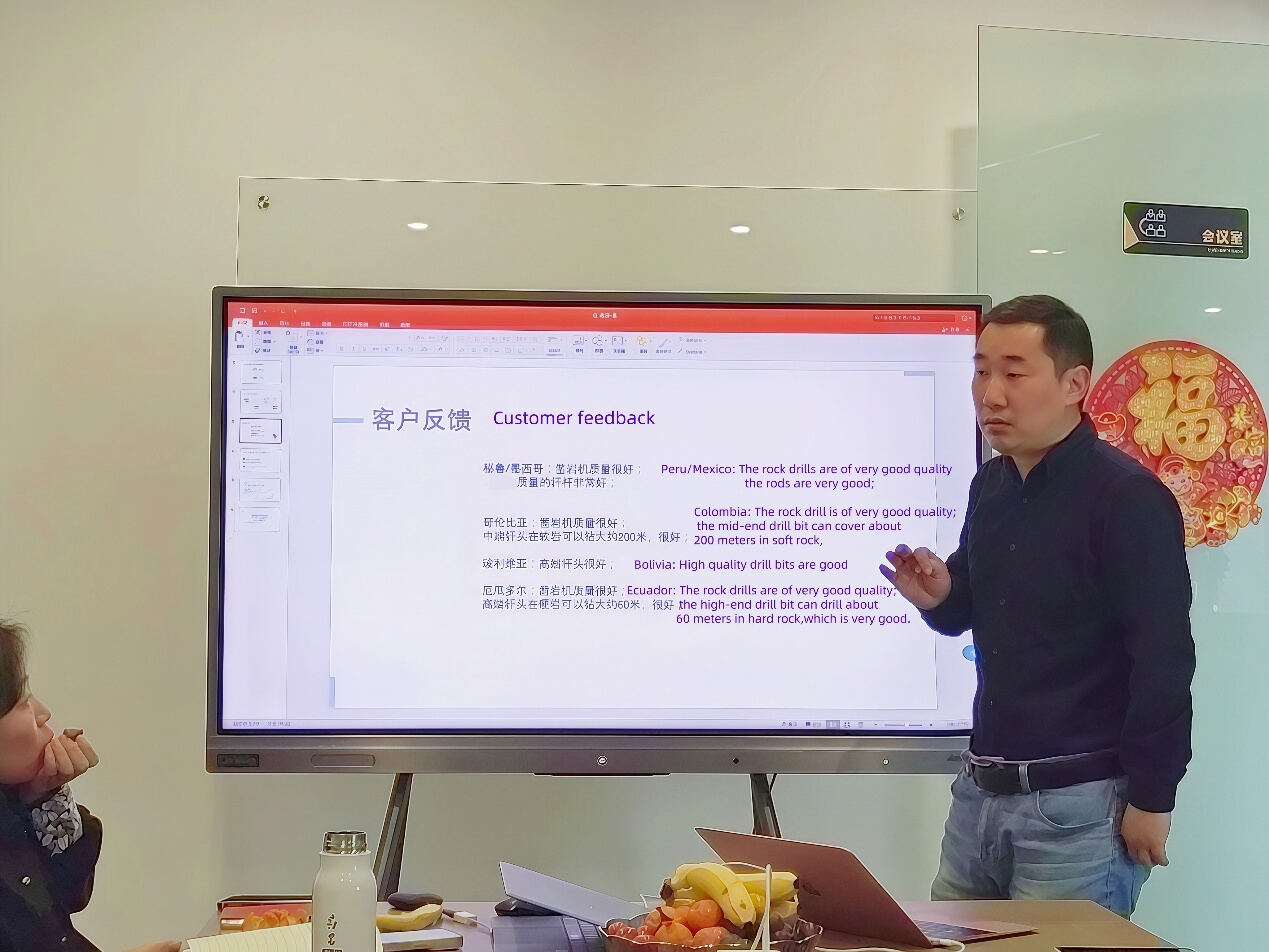

Ⅱ. Customer feedback: building a strong reputation through service

1. Satisfaction survey and case studies

Customer satisfaction reached 96%. According to the NPS (Net Promoter Score) survey, 85% of customers chose long-term cooperation due to "product durability" and "after-sales response speed";

Feedback from the Indonesian engineering party: "The life of the anti-corrosion pneumatic pick in high-humidity mining areas is extended by 40%. With the 24-hour parts delivery service, the equipment downtime is reduced by 30%, and the mining efficiency is significantly improved."

Brazilian customer evaluation: "The quick-change drill head design shortens the single-hole drill change time by 50%. With the localized service team, our drilling costs have been reduced by 25%."

2. Service system upgrade results

Three major technical service centers are deployed globally, with 200+ commonly used accessories in reserve, achieving 48-hour on-site maintenance response in core markets;

The "Rock Drill Full Life Cycle Management" service was launched to provide equipment inspection, wear analysis and energy efficiency optimization solutions for large mining companies. 10 strategic customers have been signed, and the service repurchase rate has reached 90%.

Ⅲ. Product update and upgrade: Technological innovation leads the industry trend

Pneumatic rock drill: Develop a new generation of pneumatic prototype rock drill, suitable for mining areas above 4,000 meters above sea level, and improve the air intake efficiency through turbocharging technology.

Drill bit/drill rod: Launch diamond composite (PDC) drill bit, for shale gas mining, hard sandstone tunnels and other high-hardness working conditions, the single drilling depth exceeds 1,000 meters, and the service life is 70% higher than that of traditional tungsten carbide drill bits; the hollow drill rod is made of new alloy steel, and the fracture resistance performance in the low temperature environment of -50℃ is improved by 50%;

Pneumatic pick: The high-temperature resistant pneumatic pick has an upgraded heat dissipation system, which can work continuously for 12 hours without failure in the 60℃ desert environment in the Middle East.

Ⅳ. Second quarter plan: focus on value creation and long-term win-win situation

Product side: Complete the test of electric rock drill samples and launch the "Intelligent Solution for Mining Tools";

Market side: Deeply cultivate emerging projects such as the Oyu Tolgoi Copper Mine in Mongolia and the lithium mine in Argentina, aiming to add 15 new customers with annual purchases exceeding US$500,000;

Service side: Upgrade the global after-sales system to realize the "real-time query of spare parts inventory + cross-border logistics tracking" function to further shorten the delivery cycle;

Conclusion

The growth in the first quarter of 2025 is not only a breakthrough in data, but also the practical result of the company's concept of "defining product innovation based on customer needs". From the efficiency improvement of Indonesian nickel mines, to the standard certification of Saudi tunnels, to the high-end breakthrough in the North American market, every step confirms our expertise and focus in the field of pneumatic mining tools. In the future, we will continue to use technology as a pen and service as ink to write more valuable chapters in the intelligent and green transformation of the global mining industry.

Tianjin Realon Mining Co., Ltd.

Hot News

Hot News2025-12-11

2025-09-03

2025-07-31

2025-05-30

2025-05-06

2025-04-08