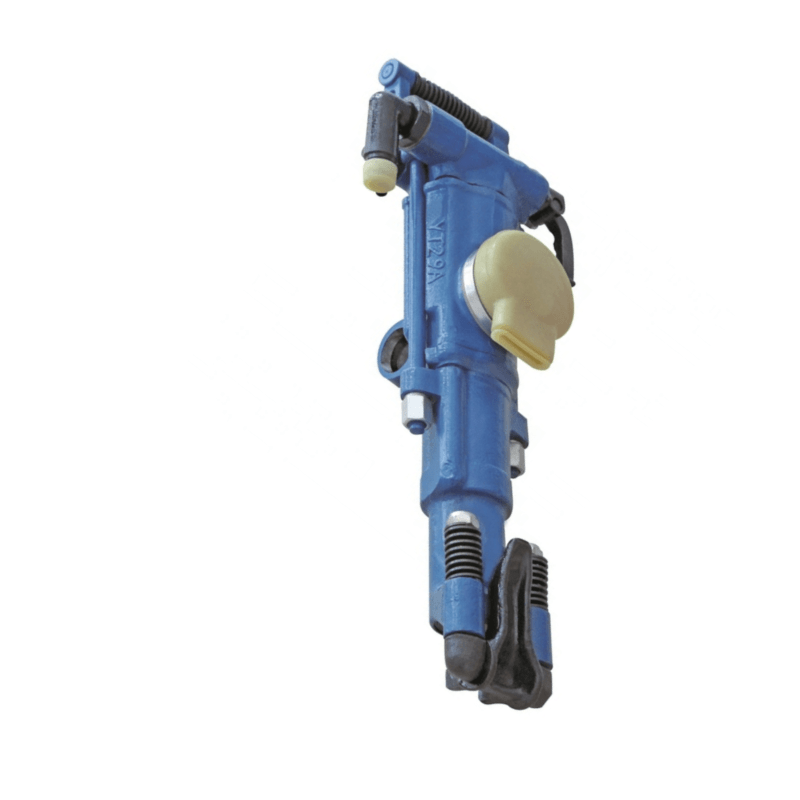

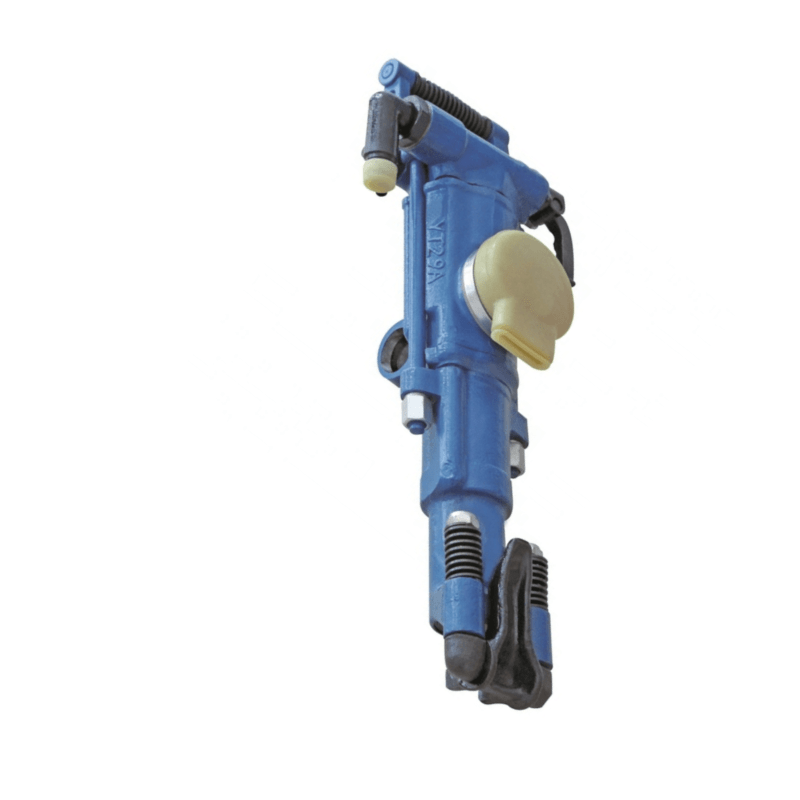

The mining and construction industries continue to evolve rapidly in 2025, with advanced drilling equipment playing a crucial role in operational efficiency and safety. Among the most essential tools in these sectors is the air leg rock drill, a pneumatic drilling machine that has revolutionized underground mining operations and tunneling projects worldwide. This versatile equipment combines portability with powerful drilling capabilities, making it indispensable for various applications ranging from small-scale construction to large mining operations.

Modern air leg rock drill technology has advanced significantly, incorporating innovative features such as improved dust collection systems, enhanced ergonomic designs, and superior drilling efficiency. These developments have made air leg rock drills more reliable and user-friendly while maintaining their reputation for durability in harsh working conditions. As we examine the leading manufacturers in 2025, it becomes evident that competition has driven remarkable innovations in this specialized equipment sector.

The global market for pneumatic drilling equipment has expanded substantially, with manufacturers focusing on developing more efficient and environmentally conscious solutions. Industry professionals increasingly demand equipment that not only delivers exceptional performance but also meets stringent safety and environmental standards. This comprehensive analysis will explore the top manufacturers who are setting industry benchmarks and driving technological advancement in air leg rock drill production.

Leading Global Manufacturers and Their Innovations

Atlas Copco Rock Drilling Solutions

Atlas Copco stands as one of the most recognized names in drilling equipment manufacturing, with their air leg rock drill series representing decades of engineering excellence. The Swedish company has consistently invested in research and development, resulting in products that offer superior drilling speed and reduced operational costs. Their latest models feature advanced automation capabilities and integrated monitoring systems that provide real-time performance data to operators.

The company's commitment to sustainability has led to the development of energy-efficient air leg rock drill models that consume less compressed air while maintaining optimal drilling performance. Atlas Copco's global service network ensures comprehensive support for their equipment, making them a preferred choice for multinational mining operations. Their innovative approach to dust suppression technology has also set new industry standards for worker safety and environmental protection.

Sandvik Mining and Rock Solutions

Sandvik has established itself as a pioneer in rock drilling technology, offering a comprehensive range of air leg rock drill equipment designed for various geological conditions. Their engineering team has developed proprietary drilling bit technologies that significantly extend operational life and improve drilling accuracy. The company's focus on modular design allows for easy maintenance and component replacement, reducing downtime in critical mining operations.

Recent innovations from Sandvik include intelligent drilling systems that automatically adjust drilling parameters based on rock conditions. Their air leg rock drill models incorporate advanced vibration dampening technology, reducing operator fatigue during extended use. The company's commitment to digital transformation has resulted in connected drilling equipment that provides valuable operational insights through cloud-based analytics platforms.

Regional Manufacturing Excellence

European Technology Leaders

European manufacturers have historically dominated the air leg rock drill market through superior engineering and stringent quality control processes. Companies like Epiroc, which spun off from Atlas Copco, continue to push technological boundaries with their innovative drilling solutions. Their latest air leg rock drill models feature enhanced ergonomics and improved power-to-weight ratios, making them ideal for challenging underground environments.

German and Finnish manufacturers have also contributed significantly to air leg rock drill technology advancement. These companies focus on precision manufacturing and incorporate advanced materials science to create more durable and efficient equipment. Their emphasis on operator safety has led to the development of comprehensive safety systems that protect workers from potential hazards associated with pneumatic drilling operations.

North American Innovation Centers

North American manufacturers have carved out significant market share by focusing on rugged, reliable air leg rock drill designs suited for harsh operating conditions. Companies like Ingersoll Rand and Chicago Pneumatic have developed specialized models for specific applications, including tunnel construction and quarrying operations. Their engineering approach emphasizes durability and ease of maintenance, crucial factors for operations in remote locations.

The integration of IoT technology into North American air leg rock drill designs has enabled predictive maintenance capabilities and remote monitoring. These features significantly reduce operational costs and improve equipment availability, making them attractive options for cost-conscious mining operations. Advanced materials and coatings developed by these manufacturers have also improved equipment longevity in corrosive environments.

Asian Market Dynamics and Manufacturing Capabilities

Chinese Manufacturing Advancement

Chinese manufacturers have rapidly emerged as significant players in the global air leg rock drill market, offering competitive products at attractive price points. Companies like Realon Heavy Industry have invested heavily in modern manufacturing facilities and quality control systems to meet international standards. Their focus on producing reliable, cost-effective air leg rock drill equipment has made them popular choices for budget-conscious operations worldwide.

The Chinese approach to air leg rock drill manufacturing emphasizes scalable production and rapid customization capabilities. Many manufacturers offer extensive customization options to meet specific customer requirements, from specialized drilling bits to modified pneumatic systems. This flexibility, combined with competitive pricing, has enabled Chinese manufacturers to gain substantial market share in developing economies and price-sensitive markets.

Japanese Precision Engineering

Japanese manufacturers bring their renowned precision engineering expertise to air leg rock drill production, creating equipment known for exceptional build quality and reliability. Companies like Furukawa and Komatsu have developed innovative hydraulic and pneumatic systems that enhance drilling efficiency while reducing maintenance requirements. Their attention to detail and quality control processes result in equipment with extended operational lifespans and consistent performance.

The Japanese approach to air leg rock drill design emphasizes continuous improvement and incremental innovation. Their manufacturers regularly incorporate feedback from field operations to refine their products, resulting in equipment that addresses real-world challenges faced by drilling operators. Advanced manufacturing techniques and quality materials ensure that Japanese air leg rock drill models maintain peak performance even under demanding operating conditions.

Technology Trends Shaping the Industry

Automation and Smart Systems

The integration of automation technology into air leg rock drill systems represents one of the most significant trends in 2025. Leading manufacturers are developing semi-automated drilling systems that can maintain optimal drilling parameters without constant operator intervention. These systems use advanced sensors to monitor drilling conditions and automatically adjust feed pressure, rotation speed, and air pressure to maximize efficiency while minimizing equipment wear.

Smart air leg rock drill systems now incorporate machine learning algorithms that analyze drilling patterns and predict optimal drilling strategies for different rock formations. This technology reduces operator skill requirements while improving overall drilling productivity. Remote monitoring capabilities allow supervisors to track equipment performance and identify potential issues before they result in costly breakdowns or safety incidents.

Environmental and Safety Innovations

Environmental consciousness has driven significant innovations in air leg rock drill design, with manufacturers developing more efficient dust collection systems and noise reduction technologies. Advanced filtration systems integrated into modern equipment capture harmful particles at the source, protecting both operators and the surrounding environment. These improvements have become essential for compliance with increasingly strict environmental regulations worldwide.

Safety enhancements in contemporary air leg rock drill designs include improved ergonomic features, vibration dampening systems, and comprehensive safety interlocks. Manufacturers are incorporating advanced materials that reduce equipment weight while maintaining structural integrity, reducing physical strain on operators during extended use. Emergency shutdown systems and fail-safe mechanisms ensure rapid response to potential hazards, significantly improving workplace safety in drilling operations.

Market Analysis and Future Outlook

Global Market Trends

The global air leg rock drill market continues to experience steady growth driven by infrastructure development and mining expansion in emerging economies. Market analysis indicates increasing demand for more efficient and environmentally friendly drilling equipment, pushing manufacturers to invest in research and development of advanced technologies. The trend toward automation and digitization is expected to accelerate, with smart drilling systems becoming standard features rather than premium options.

Regional market dynamics show varying preferences for different types of air leg rock drill equipment based on local geological conditions and operational requirements. Emerging markets show strong demand for cost-effective solutions, while developed economies increasingly prioritize advanced features and environmental compliance. This divergence has led manufacturers to develop diverse product lines targeting specific market segments and regional preferences.

Competitive Landscape Evolution

The competitive landscape for air leg rock drill manufacturing continues to evolve as new entrants challenge established players with innovative technologies and competitive pricing. Traditional manufacturers are responding by enhancing their product offerings and expanding their service capabilities to maintain market position. Strategic partnerships and acquisitions are becoming common as companies seek to combine complementary technologies and expand their global reach.

Innovation cycles in the air leg rock drill industry have accelerated, with manufacturers introducing new models and features more frequently to stay competitive. The focus has shifted from purely mechanical improvements to integrated systems that combine drilling equipment with advanced monitoring and control technologies. This evolution requires manufacturers to develop new competencies in software development and data analytics alongside their traditional engineering expertise.

Selection Criteria for Industrial Applications

Performance and Reliability Factors

When selecting an air leg rock drill for industrial applications, performance characteristics such as drilling speed, penetration rate, and energy efficiency are critical considerations. Modern equipment must demonstrate consistent performance across various rock types while maintaining reliability under demanding operating conditions. Advanced air leg rock drill models offer superior power-to-weight ratios and improved drilling accuracy, enabling faster project completion and reduced operational costs.

Reliability factors include component durability, maintenance requirements, and spare parts availability. Leading manufacturers design their air leg rock drill equipment with modular components that facilitate quick repairs and minimize downtime. The availability of local service support and technical expertise also plays a crucial role in equipment selection, particularly for operations in remote locations where rapid response to equipment issues is essential.

Operational Cost Considerations

Total cost of ownership for air leg rock drill equipment extends beyond initial purchase price to include operating expenses, maintenance costs, and productivity factors. Energy-efficient models that consume less compressed air can significantly reduce operational costs over the equipment lifetime. Advanced monitoring systems help optimize drilling parameters and identify maintenance needs before costly failures occur, further reducing total ownership costs.

Training requirements and operator skill levels also impact operational costs, with more intuitive air leg rock drill designs reducing the time and expense required to train new operators. Manufacturers that provide comprehensive training programs and ongoing technical support help customers maximize equipment productivity while minimizing operational disruptions. Long-term service agreements and parts availability guarantees provide additional cost certainty for budget planning purposes.

FAQ

What are the key advantages of modern air leg rock drill technology over traditional models

Modern air leg rock drill technology offers significant improvements in drilling efficiency, operator comfort, and environmental performance compared to traditional models. Advanced designs incorporate better vibration dampening systems that reduce operator fatigue, while improved dust collection mechanisms protect both workers and the environment. Enhanced automation features allow for more consistent drilling performance and reduce the skill level required for effective operation. Additionally, modern materials and manufacturing techniques result in more durable equipment with longer service life and reduced maintenance requirements.

How do different manufacturers compare in terms of service support and parts availability

Service support and parts availability vary significantly among air leg rock drill manufacturers, with established global companies typically offering the most comprehensive support networks. European and North American manufacturers generally provide extensive dealer networks and technical support services, while some Asian manufacturers may have limited support in certain regions. When evaluating manufacturers, consider factors such as local dealer proximity, response time commitments, training programs availability, and guaranteed parts supply for discontinued models. The best manufacturers offer comprehensive service packages that include preventive maintenance programs and rapid response to equipment failures.

What safety features should be prioritized when selecting an air leg rock drill

Essential safety features for air leg rock drill selection include comprehensive vibration dampening systems to prevent operator injury, effective dust collection mechanisms to protect respiratory health, and robust emergency shutdown capabilities. Modern equipment should incorporate ergonomic designs that reduce physical strain during operation and safety interlocks that prevent accidental startup or unsafe operation. Advanced models offer real-time monitoring of drilling parameters with automatic shutdown when unsafe conditions are detected. Additionally, consider manufacturers that provide comprehensive safety training programs and clear operational guidelines to ensure proper equipment use and maintenance.

How is digitization and IoT technology changing air leg rock drill operations

Digitization and IoT technology are revolutionizing air leg rock drill operations through real-time monitoring, predictive maintenance, and performance optimization capabilities. Modern equipment can transmit operational data to cloud-based platforms, enabling remote monitoring of drilling performance and equipment health. Machine learning algorithms analyze this data to predict optimal drilling parameters for different rock conditions and identify potential maintenance needs before failures occur. These technologies reduce operational costs, improve safety, and increase productivity while providing valuable insights for operational planning and equipment management decisions.