Self-Drilling Anchor Drill Bits for Rock & Soil | Cross/Ball-Tooth/Mud Types | Foundation & Wind Power

- Overview

- Recommended Products

- Inquiry

Product general information

Place of Origin: |

China |

Brand Name: |

Realon |

Model Number: |

Anchor Drill Bit |

Process type |

Forging |

Commercial terms of Products

Minimum Order Quantity: |

500 |

Type: |

Anchor Drill Bit |

Diameter: |

40~200mm |

Raw Material: |

40Cr Steel |

Application: |

Building, Construction, Material Fixing |

Anchor Type |

Anchor Bolt Concrete |

Color: |

Customized |

Description

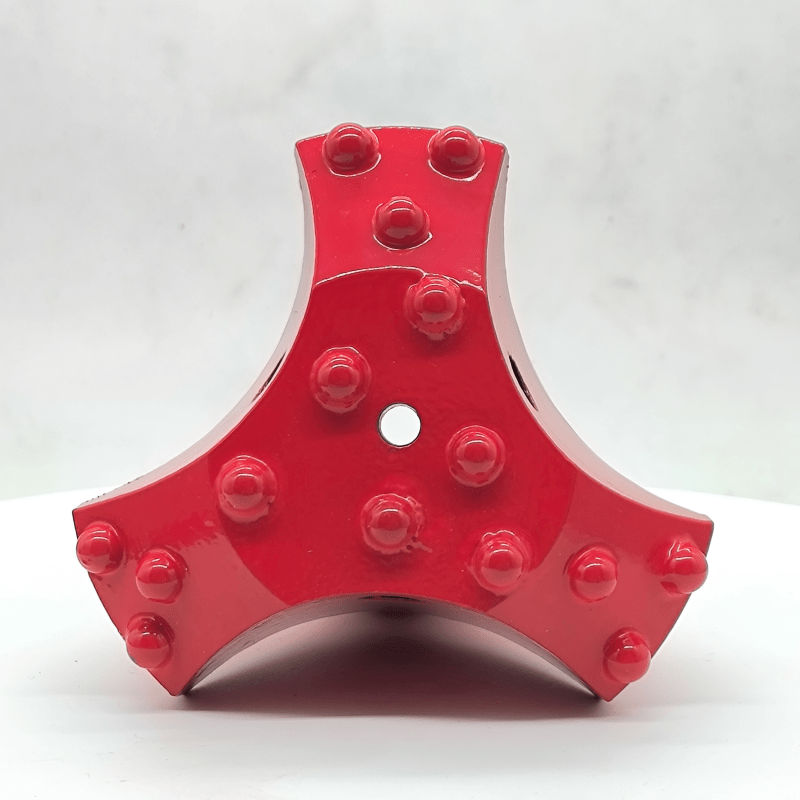

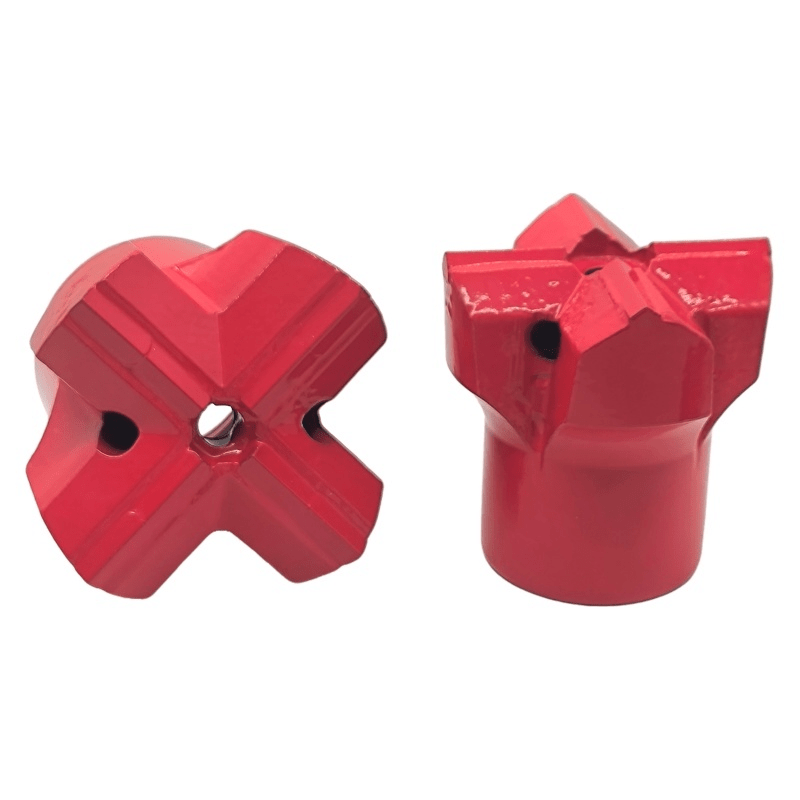

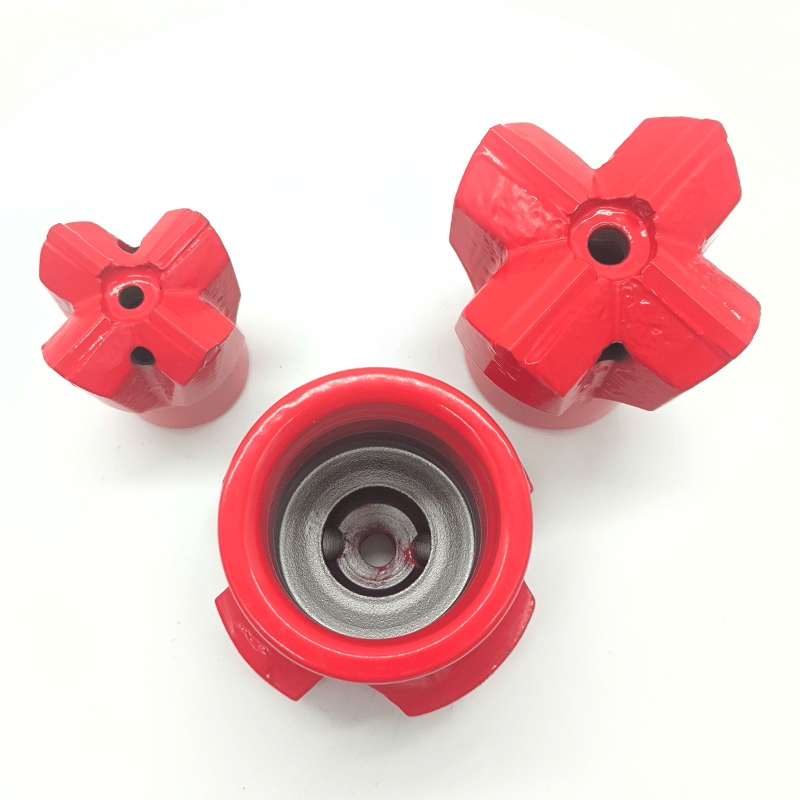

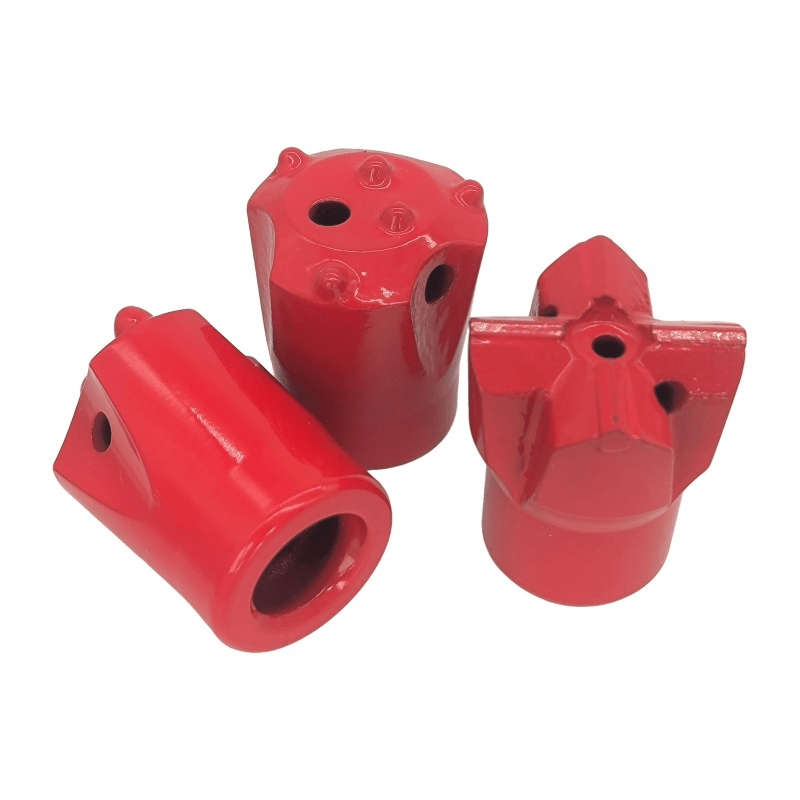

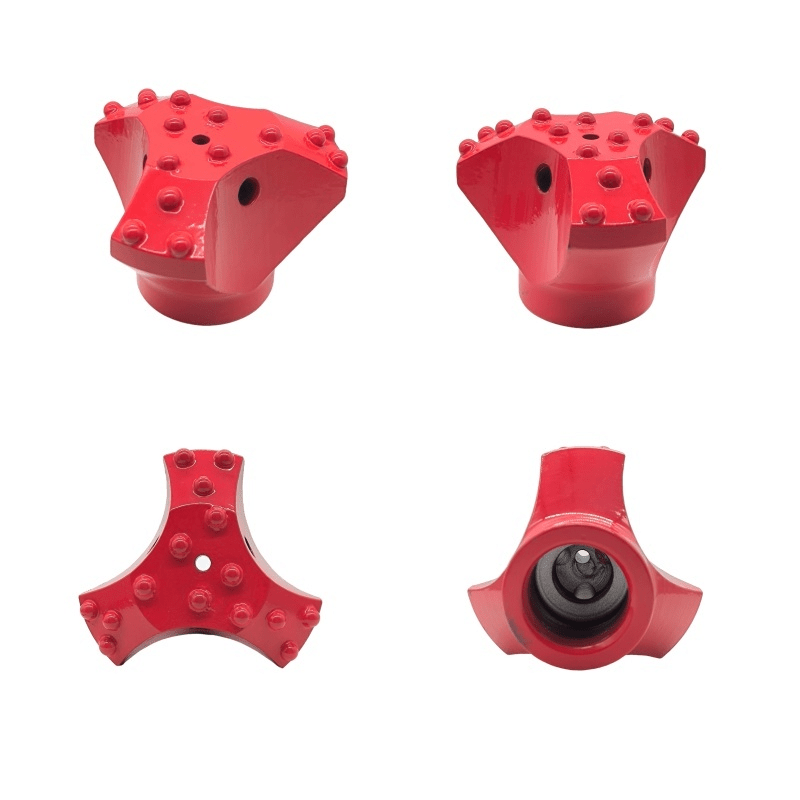

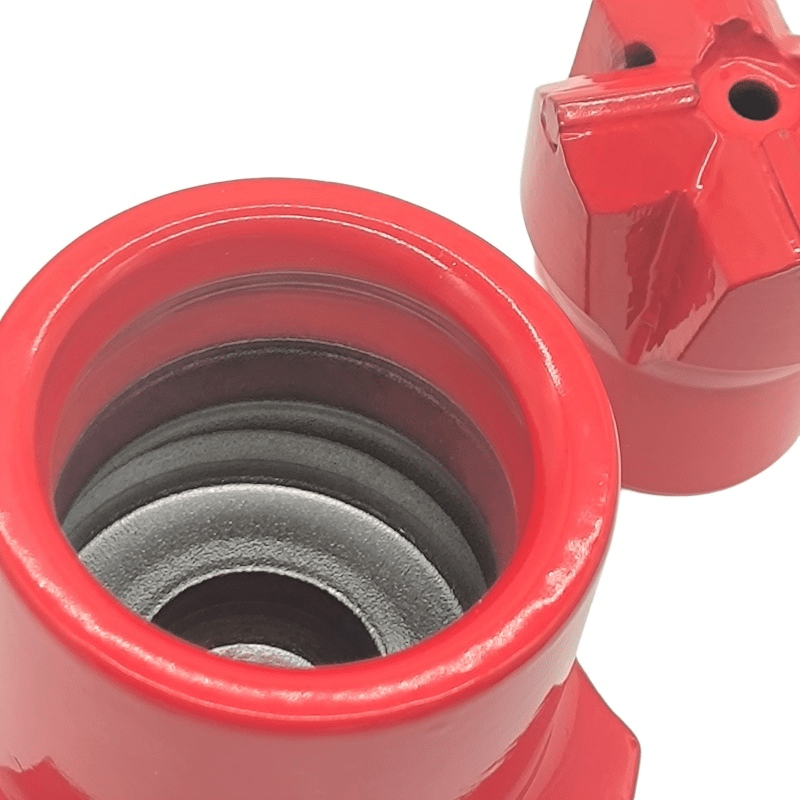

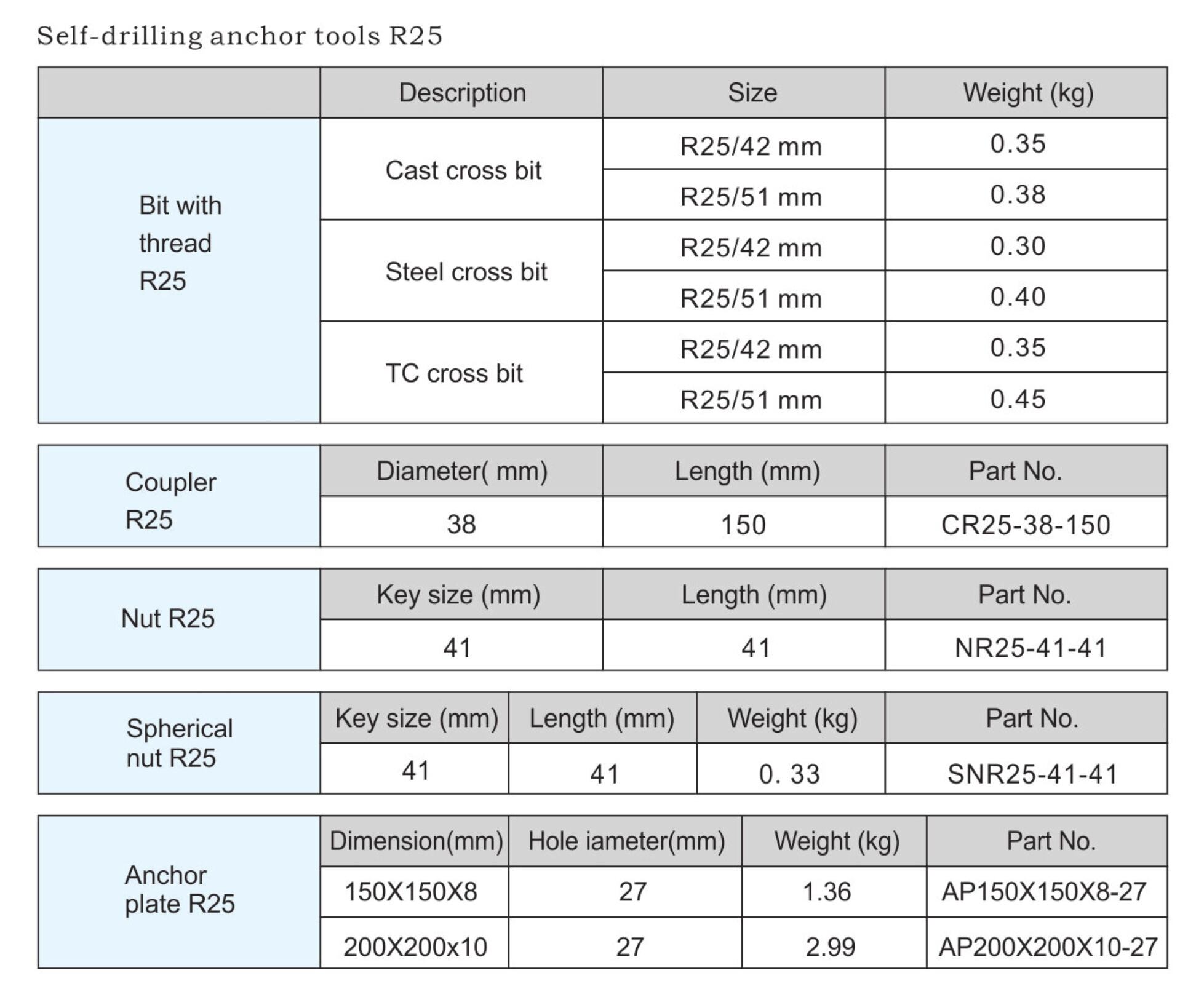

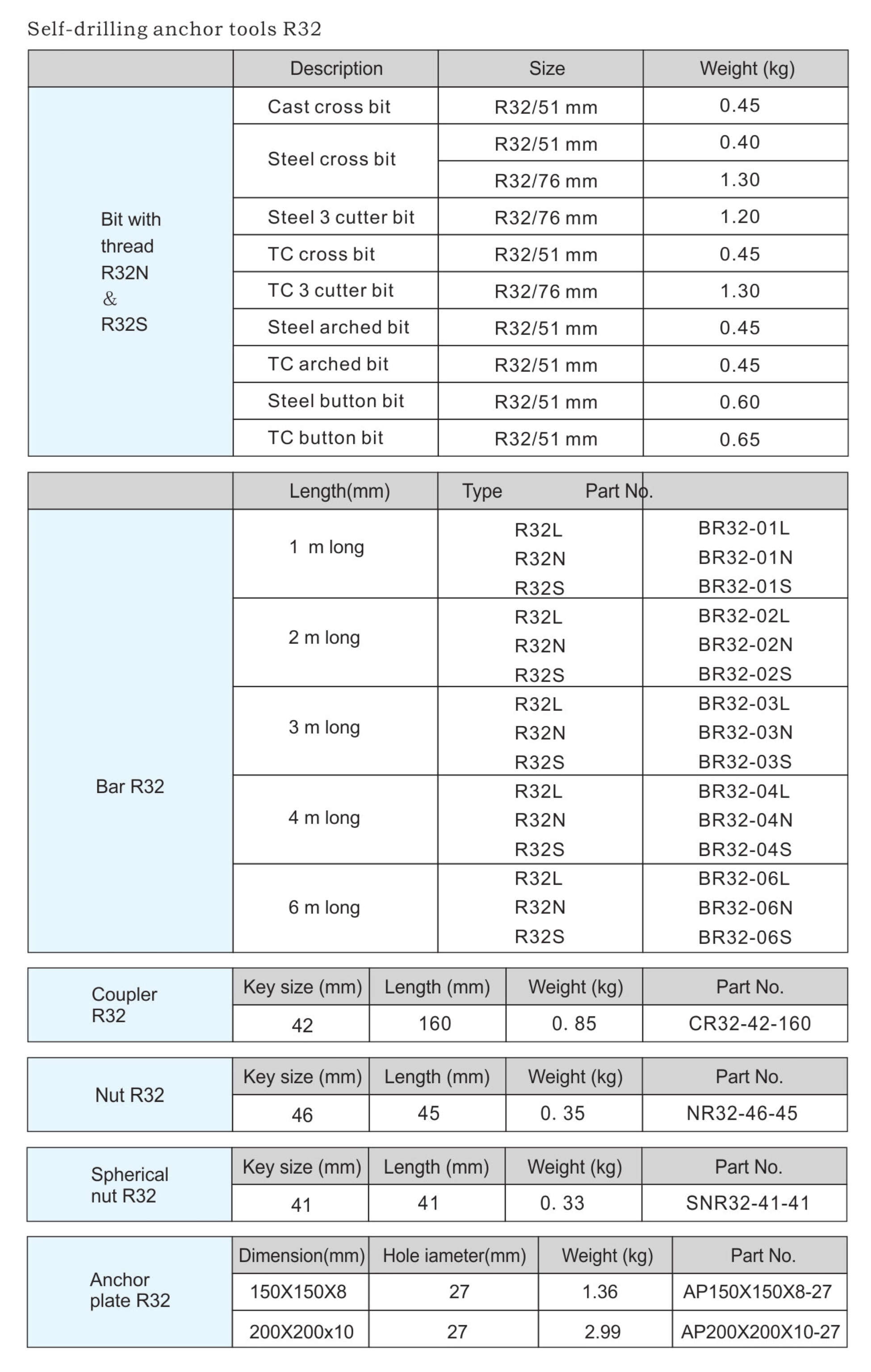

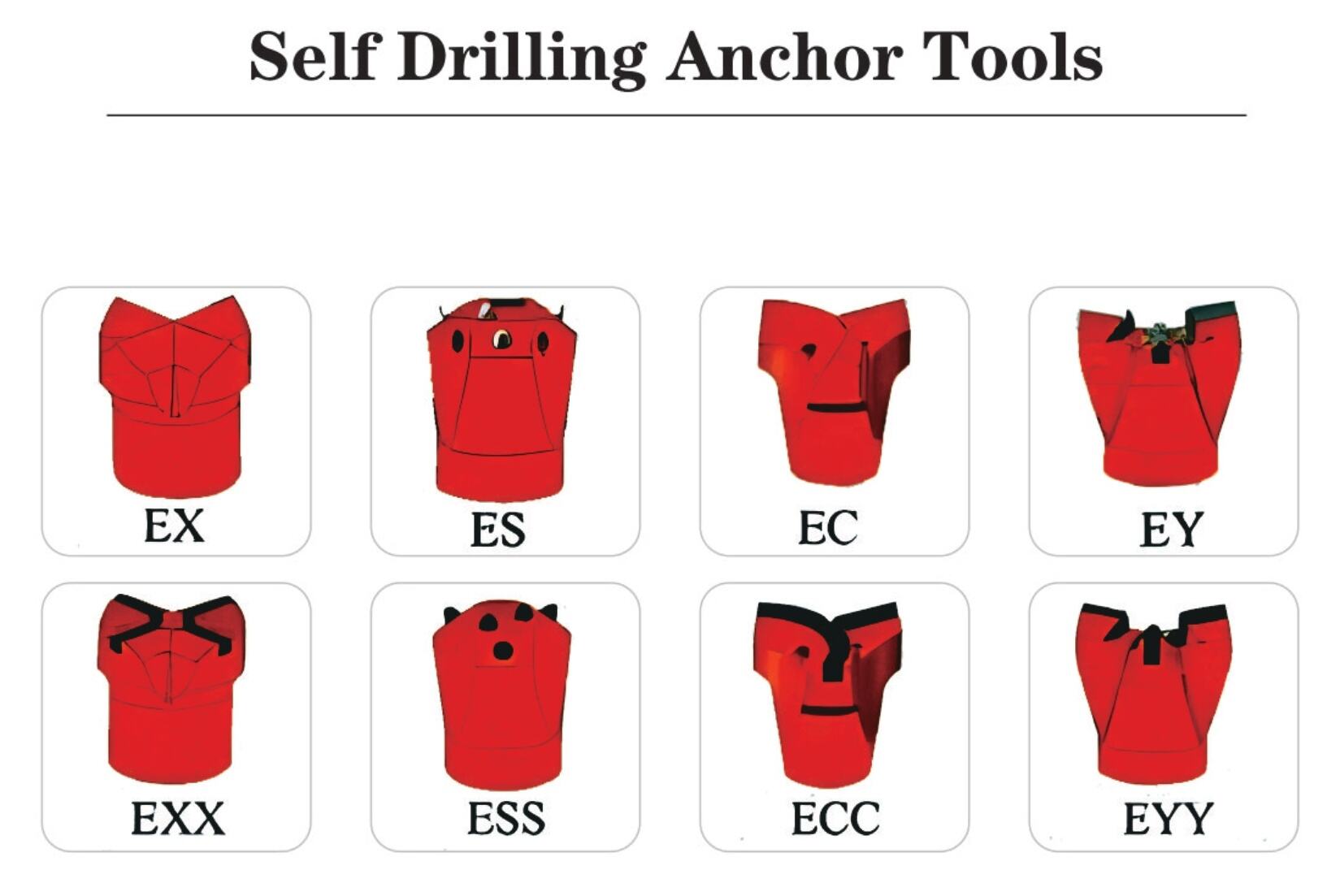

Self-drilling anchor drill bit is an important part of self-drilling anchor, and mainly include cross all-steel, cross alloy, mud drill bits, ball-tooth all-steel, ball-tooth alloy, etc. It integrates drilling and anchoring functions, and can directly anchor the anchor in the hole during the drilling process, reducing the intermediate links of traditional drilling and anchor installation, and improving construction efficiency.

| Related Products | Self Drilling Anchor Bit |

|

|

Applications

1. Foundation Reinforcement

Self-drilling anchor drill bits are used to stabilize aging buildings and infrastructure by simultaneously drilling and anchoring in soft soils or fractured bedrock.

2. Wind Power Tower Foundations

These bits secure wind turbine pile foundations in coastal or rocky terrains, ensuring stability against dynamic loads from turbine operations.

3. Coastal Protection & Retaining Walls

They anchor seawalls, breakwaters, and retaining walls in tidal zones or loose sandy soils, preventing erosion and structural failure.

4. Slope Stabilization

Ideal for reinforcing landslide-prone slopes by drilling through unstable layers and grouting anchors in a single step.

5. Urban Infrastructure Upgrades

Applied in subway tunnels and bridge retrofits where space constraints demand efficient drilling-anchoring integration.

Competitive Advantage:

1. Integrated Drilling & Anchoring Function

Combines drilling and anchor installation into a single process, eliminating traditional multi-step operations and improving construction efficiency.

2. Adaptability to Diverse Geological Conditions

Offers specialized drill bit types for different strata: mud bits for soft soil/sandy layers, ball-tooth alloy bits for medium-hard rock, ensuring optimal performance across varying environments.

3. High Drilling Efficiency

Engineered for rapid hole formation while maintaining precision, reducing project timelines compared to conventional methods.

4. Strong Anchoring Reliability

Ensures secure anchor fixation directly during drilling, effectively guaranteeing project quality and structural stability.

5. Versatile Application Scenarios

Compatible with foundation reinforcement, coastal protection, wind power foundations, and slope stabilization projects.