Next-Generation Materials Revolutionizing Drill Bit Construction

Tungsten-Carbide Alloys and Composite Blends

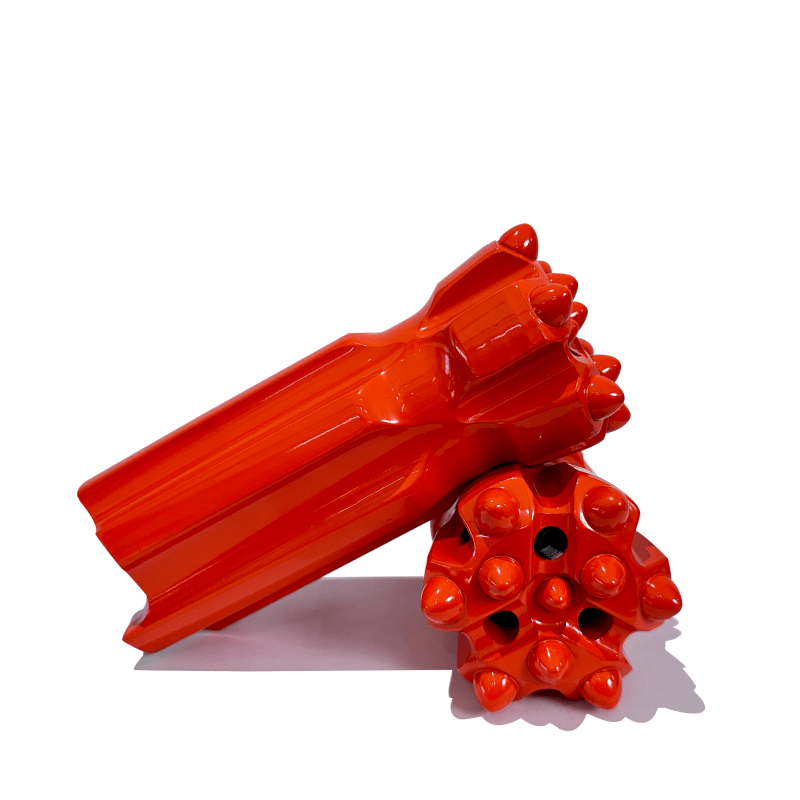

When it comes to making drill bits that can handle tough jobs, tungsten carbide has become the go-to material because it lasts longer and cuts better than most alternatives. What makes these alloys stand out is their incredible hardness level, so they don't wear down as quickly during extended drilling sessions. Manufacturers keep finding ways to improve things even more through composite blends that mix different substances together. Some recent innovations combine ceramic particles with metal fibers, giving drill bits better heat handling properties while also making them last much longer between replacements. Field tests show that these new composite materials can boost drilling speeds around 30% faster than older models, and the bits typically survive about twice as long before needing replacement. For contractors working on large projects where downtime costs money, these kinds of improvements make all the difference in getting work done efficiently.

PDC Technology and Synthetic Diamond Innovations

Polycrystalline Diamond Compact or PDC tech has changed the game for drill bits working in tough conditions. These bits use man-made diamonds made under intense pressure and heat, giving them super tough properties that resist wear better than almost anything else. The diamonds get placed right into the bit face where they slice through even the hardest rocks pretty much effortlessly. Most drilling professionals will tell anyone who'll listen that PDC bits beat traditional options hands down because they cut faster and last way longer when dealing with rough terrain. This means drillers spend less time swapping out worn bits, which cuts down on downtime and saves money over time. For companies operating in areas with especially tough geological formations, switching to PDC technology isn't just beneficial it's practically essential these days.

High-Performance Steel Matrix Developments

New advances in high performance steel matrices are making drill bits much tougher and longer lasting. Manufacturers now use methods like powder metallurgy to create these stronger steel matrices, which hold up better under tough drilling conditions. The way these bits are designed and made means they wear down slower than regular steel alternatives. Field tests actually show around a 20 percent reduction in wear rates for these premium steel bits. Many drilling companies have switched to these improved bits because they last longer between replacements. As technology keeps improving in this area, we're seeing completely new standards emerge for how long drill bits can realistically last before needing replacement.

Mechanism of Abrasion-Active Cutting Edges

Self sharpening drill bits are changing how we approach drilling tasks thanks to some pretty clever engineering behind the scenes. What makes them work is this interesting feature where the cutting edges actually stay sharp longer because they wear down the softer parts first, exposing a brand new sharp edge underneath as they go along. This means workers spend way less time stopping to resharpen or replace bits, which obviously boosts productivity when working on big projects. Manufacturing plants that switched to these self sharpening models saw real gains in how fast they could cut through materials. The consistent sharpness lasts much longer too, so there's less interruption in the workflow. Companies across different industries are starting to notice these benefits, especially when dealing with tough materials that would normally dull regular drill bits after just a few holes.

Impact on Operational Costs and Waste Reduction

Self sharpening drill bit technology is changing how much money gets spent on operations and cutting down on waste too. When drill bits last longer before needing replacement, companies save big on buying new ones all the time. Less frequent replacement means fewer old bits ending up in landfills which helps protect the environment. Industry reports show real dollar savings for businesses that switched to these bits. Some construction firms report cutting their tool budget by nearly 30% after making the switch. The environmental benefits stack up as well since there's just less metal going to waste. These improvements make financial sense while also supporting greener practices across the drilling sector. Companies are finding they can do better business while being kinder to the planet at the same time.

Advanced Surface Treatments for Extreme Conditions

Nanostructured Thermal Barrier Coatings

Thermal barrier coatings at nano scale levels are becoming essential for protecting drill bits working under brutal downhole conditions. The coatings basically act as heat shields, standing up to intense temperatures while creating a buffer zone between the metal and surrounding rock formations. Recent developments in coating application techniques have made these protective layers stick better to surfaces and last longer through repeated exposure. Research published in the Journal of Coatings Tech showed that coated tools could handle temperature fluctuations without cracking or peeling, which means they stay functional far longer than uncoated alternatives. When drilling deep into hot reservoirs or through abrasive formations, this kind of protection makes all the difference, cutting down on broken bits and costly interruptions in operations across oil fields worldwide.

Abrasion-Resistant Layer Deposition Techniques

Putting on those tough coatings to protect drill bits comes down to a few different methods, and each one brings something special to the table when it comes to fighting wear and tear. Take PVD and CVD for instance these are the big names in coating tech that let manufacturers apply protection evenly across the surface, so the drill bit doesn't get worn away as quickly during operation. What this actually means is longer lasting tools because they stay sharp much longer between sharpenings. A study published in the International Journal of Advanced Manufacturing Tech backs this up showing that properly coated bits last way longer than their uncoated counterparts, which cuts down on replacement costs and keeps operations running smoothly. For miners working deep underground where conditions are brutal, having drill bits with these tough surfaces makes all the difference. They can handle the constant grinding against rock formations without losing effectiveness, making them a smart investment for companies looking at long term sustainability in their extraction processes.

Modular Systems and Circular Economy Applications

Interchangeable Component Design Philosophy

Modular drill bit systems basically work by creating drill bits that have parts which can be switched out when needed. For mining companies, this means they can tweak their equipment faster without having to wait for whole new sets of tools. The real advantage comes from being able to replace just the worn sections rather than throwing away an entire drill bit whenever something breaks down. When parts get damaged during tough underground conditions, miners simply swap them out for fresh ones, cutting both time lost and repair bills dramatically. Many businesses find themselves saving thousands over time because they don't need to constantly buy brand new equipment but can maintain what they already own through selective part replacements.

Looking at real world applications shows just how flexible these systems can be. Take down-the-hole drilling in mines as an example some operators have started using modular bits that work better when moving between different types of rock formations. The cost savings are obvious but what really stands out is how well they handle those unique drilling challenges that pop up all the time in field conditions. Modular parts actually help reduce waste over time since companies don't need to stockpile so many specialized tools. When customization aligns with basic functionality, we see significant improvements in both operational efficiency and environmental impact across drilling operations.

Environmental Benefits of Partial Bit Recycling

Recycling parts from old drill bits actually gives quite a few environmental benefits that fit right in with circular economy ideas in mining operations. When companies take apart these bits and reuse certain pieces, they cut down on waste going to landfills, save money on raw materials, and basically hurt the environment less than if everything went straight to trash. The steel and tungsten carbide from worn out bits get put back into production instead of sitting unused forever. Some mines have started programs where they collect used bits from contractors, break them down at specialized facilities, then sell or repurpose the good parts. This not only helps protect our planet's limited resources but also makes financial sense for businesses looking to reduce costs over time.

Looking at numbers shows that conserving resources via recycling really cuts down on waste generation. Take drill bits for instance - some studies show that when companies recycle just part of these tools, they cut material waste by around 40% or so. This makes a real difference in terms of environmental footprint. When businesses start implementing these kinds of recycling programs, it actually pushes engineers to think differently about how they design drill bits themselves. They find ways to make them last longer while still getting the job done properly. The mining sector has been slowly embracing circular economy ideas lately. This shift helps improve their green image certainly, but more importantly creates actual practices that safeguard our environment long term rather than just talking about it.

Sustainable Mining Through Drill Bit Innovation

Reducing Energy Consumption Per Meter Drilled

New developments in drill bit tech play a big role in cutting down how much energy it takes to drill each meter, which helps make mining more sustainable overall. Advanced drill bits made with modern materials and better shaped for airflow actually cut through rock with less resistance, saving quite a bit of energy in the process. Take composite materials as an example they're now being used in making these bits, and this makes them last longer while needing less power to operate. Many people working on sustainable mining stress just how important it is to save energy. When companies spend less on power bills, their bottom line improves, plus there's obviously less harm done to the environment. All this fits right into bigger picture sustainability targets too. The mining industry is getting greener by the day, so adopting these new drill bit technologies isn't just smart business it's becoming necessary if companies want to keep extracting minerals without wrecking the planet.

Supporting Low-Impact Mineral Extraction Goals

The latest drilling tech is making a big difference in how minerals get extracted with less environmental impact, which fits right into what sustainable development means for mining operations today. Better designed drill bits help cut down on nature disruption during extraction processes. These newer bits allow miners to dig precisely where they need to go, wasting less material and leaving smaller scars on the land surface. Most mining companies now have green goals they want to hit, and improved drilling tech helps them reach those targets through cleaner, less intrusive ways of getting at underground resources. Regulations like the UN's Sustainable Development Goals actually back up this kind of eco-friendly mining approach that protects ecosystems while still tapping into valuable resources. When mines switch to these lower impact technologies, they're not just following rules but showing real commitment to managing natural resources responsibly. This shift could really change how the whole industry operates moving forward toward something much greener.

FAQ

What are tungsten-carbide alloys used for in drill bit construction?

Tungsten-carbide alloys are used for their exceptional durability and cutting efficiency, significantly reducing wear and extending the lifespan of drill bits.

How does PDC technology benefit drill bit performance?

PDC technology utilizes synthetic diamonds for unparalleled hardness and wear resistance, allowing drill bits to cut through hard rock formations effectively, reducing operational costs due to less frequent bit replacements.

What are the advantages of self-sharpening drill bits?

Self-sharpening drill bits maintain sharpness via abrasion-active cutting edges, reducing downtime for sharpening or replacement, thus improving overall drilling efficiency.

How do advanced surface treatments protect drill bits?

Advanced surface treatments like nanostructured thermal barrier coatings and abrasion-resistant layer deposition enhance drill bit durability and wear resistance, minimizing equipment failures in extreme drilling conditions.

What is the significance of modular drill bit systems?

Modular drill bit systems offer interchangeable components, allowing quick replacement of worn-out parts, enhancing operational flexibility and reducing maintenance costs.

How does partial bit recycling aid in environmental sustainability?

Partial recycling of drill bits conserves resources, reduces waste, and aligns with the principles of the circular economy, minimizing the mining industry's ecological footprint.