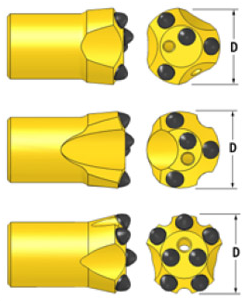

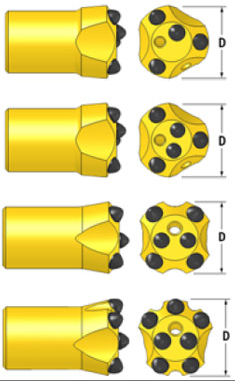

7°11°12°Taper Button Drill Bit For Rock

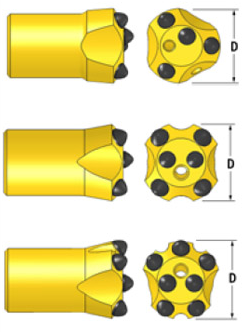

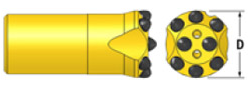

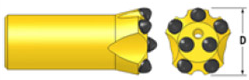

A tapered drill bit is the core rock-breaking component that connects to the drill rod via a precision conical interface. This robust design ensures direct and efficient transfer of impact energy for fast drilling in various rock conditions. Fitted with wear-resistant carbide buttons (spherical, parabolic, ballistic or conical) and optimized flushing holes, it delivers long service life and smooth slag removal. Ideal for mining, quarrying, and construction applications, it offers a reliable, cost-effective solution with quick changeover and low maintenance.

- Overview

- Video

- Recommended Products

- Inquiry

-

Superior Force Transmission for Efficient Rock Breaking

The precision-engineered tapered connection ensures direct and efficient energy transfer from the drill rod to the bit, maximizing impact energy delivery and increasing rock breaking efficiency in various drilling applications. This robust tapered socket design guarantees reliable performance in demanding conditions, reducing energy loss and improving overall drilling speed for mining and construction projects. -

Cost-Effective Simplicity and Ease of Maintenance

Featuring a straightforward and durable tapered drill bit design without complex moving parts, this tool offers exceptional reliability and reduced maintenance requirements. Its simple construction allows for quick and easy bit changes on site, minimizing downtime and lowering operational costs for quarry drilling, civil engineering projects, and small-scale mining operations. -

Exceptional Durability in Hard Rock Formations

Manufactured using high-grade heat-treated alloy steel and premium carbide inserts, our tapered drill bits demonstrate outstanding wear resistance and structural integrity when drilling through abrasive and hard rock layers. The optimized material composition and heat treatment process significantly extend service life, providing excellent value for tough drilling conditions in granite, basalt, and other challenging geological formations. -

Wide Compatibility Across Drilling Equipment

With standardized taper angles and dimensions compatible with most rock drill models, these tapered bits offer versatile application across multiple platforms. This interoperability makes them an ideal choice for contractors operating diverse equipment fleets, ensuring consistent performance whether used with hydraulic, pneumatic, or electric drilling systems in construction, mining, or water well drilling operations. -

Stable Drilling Performance with Reduced Vibration

The secure tapered fit provides enhanced drilling stability and minimizes vibration during operation, resulting in straighter boreholes and reduced stress on drilling equipment. This vibration-dampening characteristic contributes to longer equipment lifespan and improved drilling accuracy for precision-critical applications like anchor drilling, foundation work, and rock bolting projects.

Product general information

Degree of Taper |

7° / 11° / 12° |

Diameter |

30 - 50 mm |

Process |

Fully forged, hot-pressed tooth insert |

Application |

Mining, Quarrying, Tunneling, Construction |

Color |

Black / Yellow / Red / Blue / Golden (Support customized) |

Place of Origin |

China |

Common Dimension | |

Button bit |

Diameter |

No X button diameter |

Flushing hole |

Weight aprox kg |

||||

mm |

Inch |

Front |

Gauge |

Angle |

Front |

Side |

||

|

Button bit, Short skirt

|

32 |

1 1/4 |

1X8 |

3X8 |

35° |

1 |

1 |

0.24 |

33 |

1 19/64 |

2X7 |

5X7 |

35° |

2 |

1 |

0.26 |

|

34 |

1 11/32 |

2X7 |

4X7 |

40° |

1 |

1 |

0.29 |

|

35 |

1 3/8 |

2X7 |

5X8 |

35° |

1 |

1 |

0.33 |

|

36 |

1 27/64 |

1X8 |

3X9 |

40° |

1 |

1 |

0.37 |

|

36 |

1 27/64 |

2X7 |

5X8 |

35° |

1 |

1 |

0.37 |

|

38 |

1 1/2 |

1X8 |

3X9 |

35° |

1 |

1 |

0.38 |

|

38 |

1 1/2 |

2X7 |

5X8 |

35° |

1 |

1 |

0.38 |

|

38 |

1 1/2 |

2X7 |

5X9 |

40° |

2 |

1 |

0.38 |

|

40 |

1 37/64 |

1X8 |

3X9 |

30° |

1 |

1 |

0.40 |

|

40 |

1 37/64 |

1X9 |

3X10 |

30° |

1 |

1 |

0.40 |

|

40 |

1 37/64 |

1X9 |

3X9 |

35° |

1 |

1 |

0.40 |

|

40 |

1 37/64 |

2X7 |

5X9 |

35° |

1 |

1 |

0.40 |

|

42 |

1 21/32 |

1X8 |

3X9 |

30° |

1 |

1 |

0.43 |

|

42 |

1 21/32 |

1X9 |

3X10 |

30° |

1 |

1 |

0.43 |

|

42 |

1 21/32 |

1X9 |

3X9 |

35° |

1 |

1 |

0.43 |

|

42 |

1 37/64 |

2X8 |

5X9 |

35° |

1 |

1 |

0.43 |

|

|

Long skirt

|

32 |

1 1/4 |

2X7 |

5X7 |

35° |

1 |

1 |

0.30 |

33 |

1 19/64 |

2X7 |

5X7 |

35° |

1 |

1 |

0.31 |

|

35 |

1 3/8 |

2X7 |

5X8 |

35° |

1 |

1 |

0.36 |

|

38 |

1 1/2 |

2X7 |

5X9 |

35° |

1 |

1 |

0.41 |

|

41 |

1 5/8 |

2X7 |

5X9 |

35° |

1 |

1 |

0.42 |

|

|

Button bit,Short skirt

|

32 |

1 1/4 |

1X8 |

3X8 |

35° |

1 |

2 |

0.24 |

32 |

1 1/4 |

2X7 |

5X7 |

40° |

1 |

1 |

0.24 |

|

33 |

1 19/64 |

2X7 |

4X7 |

40° |

1 |

1 |

0.25 |

|

34 |

1 11/32 |

2X7 |

4X7 |

40° |

1 |

1 |

0.29 |

|

35 |

1 3/8 |

2X7 |

5X7 |

35° |

1 |

1 |

0.33 |

|

35 |

1 3/8 |

2X7 |

5X8 |

35° |

1 |

1 |

0.33 |

|

36 |

1 27/64 |

1X8 |

3X9 |

40° |

1 |

1 |

0.36 |

|

36 |

1 27/64 |

2X7 |

4X7 |

40° |

1 |

1 |

0.36 |

|

36 |

1 27/64 |

2X7 |

5X8 |

35° |

1 |

1 |

0.36 |

|

38 |

1 1/2 |

1X9 |

3X9 |

40° |

1 |

1 |

0.39 |

|

38 |

1 1/2 |

2X8 |

3X9 |

40° |

1 |

1 |

0.39 |

|

38 |

1 1/2 |

2X7 |

5X8 |

35° |

1 |

1 |

0.39 |

|

38 |

1 1/2 |

2X7 |

5X9 |

35° |

1 |

1 |

0.39 |

|

40 |

1 37/64 |

1X9 |

3X9 |

40° |

1 |

1 |

0.40 |

|

40 |

1 37/64 |

2X8 |

3X9 |

40° |

1 |

1 |

0.40 |

|

40 |

1 37/64 |

2X9 |

3X9 |

40° |

1 |

2 |

0.40 |

|

40 |

1 37/64 |

2X7 |

5X9 |

35° |

1 |

1 |

0.40 |

|

40 |

1 37/64 |

2X8 |

5X9 |

35° |

1 |

1 |

0.40 |

|

41 |

1 5/8 |

2X7 |

5X9 |

35° |

1 |

1 |

0.41 |

|

|

|

32 |

1 1/4 |

2X7 |

5X7 |

35° |

1 |

1 |

0.30 |

33 |

1 19/64 |

2X7 |

5X7 |

35° |

1 |

1 |

0.31 |

|

33 |

1 19/64 |

2X7 |

5X7 |

40° |

2 |

1 |

0.31 |

|

35 |

1 3/8 |

2X7 |

5X7 |

40° |

2 |

1 |

0.35 |

|

38 |

1 1/2 |

2X7 |

5X9 |

35° |

1 |

1 |

0.41 |

|

41 |

1 5/8 |

2X7 |

5X9 |

35° |

1 |

1 |

0.42 |

|

|

35 |

1 3/8 |

2X7 |

5X9 |

35° |

1 |

1 |

0.38 |

36 |

1 27/64 |

2X7 |

5X9 |

35° |

1 |

1 |

0.39 |

|

38 |

1 1/2 |

2X7 |

5X9 |

35° |

1 |

1 |

0.41 |

|

41 |

1 5/8 |

2X7 |

5X9 |

35° |

1 |

1 |

0.42 |

|

|

Button bit,Short skirt

|

28 |

1 7/64 |

1X7 |

3X7 |

20° |

1 |

1 |

0.20 |

28 |

1 7/64 |

1X7 |

4X7 |

35° |

1 |

1 |

0.20 |

|

29 |

1 9/64 |

1X7 |

3X7 |

40° |

1 |

1 |

0.21 |

|

30 |

1 3/16 |

1X7 |

3X7 |

40° |

1 |

1 |

0.22 |

|

30 |

1 3/16 |

1X7 |

4X7 |

35° |

1 |

1 |

0.22 |

|

30 |

1 3/16 |

2X7 |

4X7 |

30° |

1 |

1 |

0.22 |

|

32 |

1 1/4 |

2X7 |

5X7 |

40° |

2 |

1 |

0.24 |

|

33 |

1 19/64 |

2X7 |

5X7 |

35° |

1 |

1 |

0.25 |

|

34 |

1 11/32 |

2X7 |

5X8 |

35° |

1 |

1 |

0.29 |

|

35 |

1 3/8 |

2X7 |

4X7 |

35° |

1 |

1 |

0.33 |

|

35 |

1 3/8 |

2X7 |

5X8 |

35° |

2 |

1 |

0.33 |

|

35 |

1 3/8 |

2X7 |

5X9 |

35° |

1 |

1 |

0.33 |

|

36 |

1 27/64 |

2X7 |

5X9 |

35° |

1 |

1 |

0.37 |

|

37 |

1 29/64 |

2X7 |

5X9 |

40° |

1 |

1 |

0.38 |

|

38 |

1 1/2 |

1X9 |

3X9 |

40° |

1 |

1 |

0.40 |

|

38 |

1 1/2 |

2X7 |

5X9 |

35° |

1 |

1 |

0.40 |

|

41 |

1 5/8 |

2X7 |

5X9 |

35° |

1 |

1 |

0.41 |

|

|

Long skirt

|

32 |

1 1/4 |

2X7 |

5X7 |

35° |

1 |

1 |

0.30 |

33 |

1 19/64 |

2X7 |

5X7 |

35° |

1 |

1 |

0.31 |

|

33 |

1 19/64 |

2X7 |

6X7 |

40° |

2 |

1 |

0.31 |

|

35 |

1 3/8 |

2X7 |

6X7 |

40° |

2 |

1 |

0.35 |

|

38 |

1 1/2 |

2X7 |

5X9 |

35° |

1 |

1 |

0.41 |

|

41 |

1 5/8 |

2X7 |

5X9 |

35° |

1 |

1 |

0.42 |

|

|

35 |

1 3/8 |

2X7 |

5X9 |

35° |

1 |

1 |

0.38 |

36 |

1 27/64 |

2X7 |

5X9 |

35° |

1 |

1 |

0.39 |

|

38 |

1 1/2 |

2X7 |

5X9 |

35° |

1 |

1 |

0.41 |

|

41 |

1 5/8 |

2X7 |

5X9 |

35° |

1 |

1 |

0.42 |

|

Contact us for customized solutions based on your unique requirements

Competitive Advantage

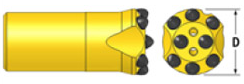

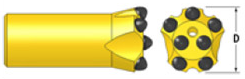

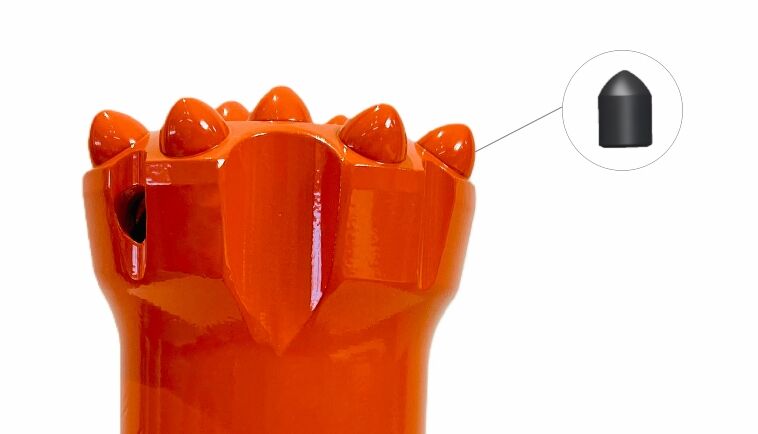

Different Types of Button

|

1.Spherical Button Crafted with high-grade carbide, this spherical button bit delivers exceptional wear resistance and low rotation resistance, making it the ideal solution for highly abrasive and corrosive hard rock formations. Its robust design ensures reliable performance under extreme conditions. |

2.Parabolic Button Engineered for superior penetration and balanced durability, it achieves fast drilling progress in medium-hard rock with moderate corrosiveness. Its versatile design combines efficient cutting with strong wear resistance, offering wide applicability across diverse job sites. |

|

|

|

3.Conical Button Designed for maximum penetration force and high drilling speed, the conical button bit excels in non-corrosive formations. Its optimized geometry makes it particularly suitable for small-diameter applications where precision and efficiency are critical. |

4. Ballistic Button Specialized for rapid advancement in soft rock conditions, the ballistic button bit delivers smooth, efficient progress in non-corrosive ground. Its streamlined profile minimizes resistance while maintaining consistent performance in softer formations. |

|

|

Optimized Manufacturing Process for Drill Bits

1.High-Strength Material Selection and Cutting

Premium alloy round steel is precision-cut to specified dimensions, creating optimized drill bit blanks ready for forging.

2.High-Pressure Hot Forging Process

Steel blanks are heated and forged under extreme pressure to form the fundamental bit structure with enhanced material density.

3.Initial Machining and Shape Formation

The forged components undergo rough turning operations to establish basic dimensional accuracy and prepare for detailed machining.

4.Advanced Heat Treatment Technology

Specialized heating and cooling cycles dramatically improve the bit's mechanical properties, delivering superior hardness and impact resistance.

5.Precision Carbide Hole Engineering

Accurate holes for carbide inserts are drilled with exacting tolerances, followed by comprehensive dimensional verification.

6.Critical Feature Machining Operations

Strategic drilling, spline milling, and optimized slag discharge slots are machined to enhance drilling performance.

7.Secure Carbide Insert Installation

High-grade carbide buttons are permanently fixed using thermal expansion or precision press-fit methods for maximum retention.

8.Surface Enhancement and Protection

Final precision turning is followed by advanced polishing, protective painting, and corrosion-resistant coating applications.

9.Quality-Verified Packaging Solution

Finished drill bits undergo final inspection before professional packaging, ensuring perfect condition during storage and transit.

Applications

● Underground and surface mining

● Tunneling and infrastructure drilling

● Water well and drainage boreholes

● Geological and core exploration